Skyscraper models are an essential part of modern architecture and urban design. These models serve as physical representations of large-scale buildings that reach towering heights and push the boundaries of engineering. Skyscraper models not only demonstrate the scale and design of these architectural wonders, but they also provide a tangible way to visualize and communicate the complexities involved in constructing skyscrapers.

Whether it’s for city planning, educational purposes, or simply as a form of artistic expression, the significance of skyscraper models cannot be overstated. In this guide, we will explore the history, types, techniques, and importance of skyscraper models, along with the materials used to build them. Additionally, we will delve into the processes involved in designing skyscraper models, the tools and technologies that aid in their creation, and how they are used for various purposes in the construction and design industries.

The History of Skyscraper Models

Early Models and Their Importance

The history of skyscraper models can be traced back to the late 19th century, during the construction of the first true skyscrapers. As the Industrial Revolution progressed and cities grew in size, there was a need for buildings that could house more people and businesses within a limited urban space. Skyscrapers, with their soaring heights and modern designs, became a symbol of human ingenuity and architectural achievement.

Early skyscraper models were often simple and made of basic materials like wood and cardboard. These models were primarily used to convey the concept of verticality and spatial organization, allowing architects, engineers, and city planners to visualize and refine their ideas.

The Rise of Modern Skyscraper Models

As the field of architecture advanced, so too did the complexity and scale of skyscraper models. By the mid-20th century, skyscraper models had evolved into intricate, highly detailed representations of the buildings they depicted. With advancements in materials, construction techniques, and technology, these models became more accurate and realistic. Today, skyscraper models are often made from high-quality materials such as acrylic, foam, and 3D-printed components, enabling greater precision and detail.

Why Are Skyscraper Models Important?

The Role of Skyscraper Models in Design and Planning

Skyscraper models play a crucial role in the design and planning of tall buildings. They provide architects, engineers, and developers with a visual representation of how a proposed skyscraper will look within the context of its surrounding environment. This is especially important in densely populated urban areas where new buildings can drastically alter the skyline and impact the surrounding community.

By creating a physical model, designers can examine the building’s proportions, scale, and overall aesthetic. Models allow for early testing of various design elements such as the structure, height, massing, and materials, helping to ensure that the final product will meet both functional and visual requirements.

The Benefits of Skyscraper Models in Client Presentations

Skyscraper models are also invaluable tools for presenting design proposals to clients, stakeholders, and the public. A tangible model can make the architectural vision come to life, offering a clearer understanding of how the building will fit into the surrounding landscape. This is particularly important for large projects where stakeholders may struggle to visualize the impact of the building from architectural drawings alone.

In many cases, skyscraper models are used to secure funding and approval for a project. A detailed, high-quality model can convey professionalism, attention to detail, and the potential success of the project, increasing confidence among investors and clients.

Skyscraper Models for Educational Purposes

In addition to their use in professional settings, skyscraper models also serve an educational purpose. They are often featured in museums, universities, and schools as part of architectural exhibits or courses. Students of architecture and engineering can learn valuable lessons about building design, construction techniques, and materials by studying these models. Moreover, they provide a hands-on learning experience, helping students develop a deeper understanding of how skyscrapers are designed and constructed.

Types of Skyscraper Models

Scale Models

One of the most common types of skyscraper models is the scale model, which is a reduced-size representation of the actual building. Scale models are usually created in 1:100, 1:200, or 1:500 scales, depending on the level of detail required and the size of the project. The smaller the scale, the less detail can be included, but it still provides a general sense of the building’s proportions.

Scale models are particularly useful for conveying the overall design and layout of the building, and they can be used to demonstrate how the skyscraper will interact with its environment. These models are often created using materials like foam board, acrylic, and 3D printing.

3D-Printed Models

In recent years, 3D printing has revolutionized the creation of skyscraper models. With this technology, architects and designers can produce highly detailed models with greater precision and speed. 3D-printed skyscraper models allow for intricate features, such as windows, doors, and textures, to be incorporated into the design without the need for manual labor.

3D printing also allows for easier adjustments during the design process, as changes can be made quickly and efficiently. This makes it easier for designers to test different configurations and materials, speeding up the decision-making process and improving the final design.

Digital Models and Virtual Simulations

While physical models remain popular, digital models are increasingly being used in the design process. These models are created using specialized software that allows designers to manipulate and adjust the model virtually. Virtual simulations and 3D renderings are often used to showcase how a skyscraper will look in different lighting conditions, with varying weather patterns, or from different angles.

Digital models can be shared with clients and stakeholders easily, allowing for remote collaboration and feedback. Additionally, they can be integrated with other technologies, such as virtual reality (VR), to create immersive presentations that give a more realistic experience of the building before it is even constructed.

Techniques for Creating Skyscraper Models

Traditional Modeling Techniques

Creating a skyscraper model using traditional methods involves handcrafting each component and assembling them together. Materials such as cardboard, foam, plastic, and wood are often used in this process. Traditional modeling techniques require a high level of craftsmanship and attention to detail, as each part must be measured and cut precisely to scale.

Modelers use tools such as knives, glue, rulers, and compasses to create intricate parts of the model, including the building’s façade, windows, and roof. This technique is often used for scale models and is still employed by many architects and model makers today, especially for smaller-scale projects.

Modern Digital Fabrication

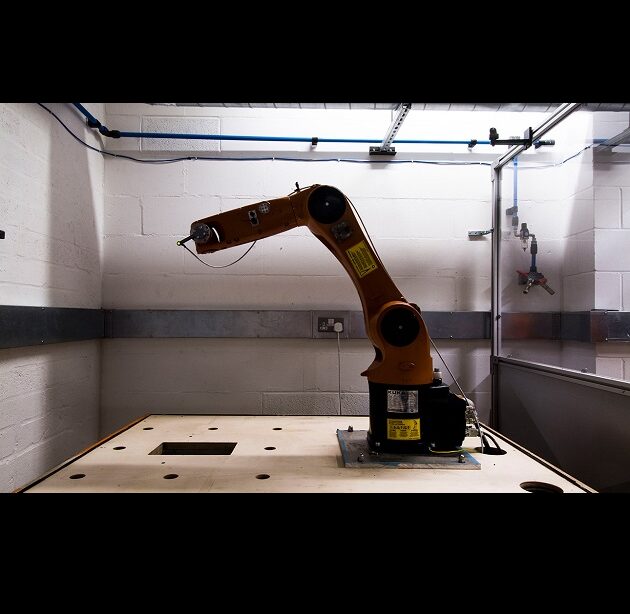

With the advent of modern digital fabrication technologies, the creation of skyscraper models has become more efficient and precise. Techniques such as laser cutting, CNC milling, and 3D printing allow for the rapid production of complex parts that can be assembled into a larger model.

Laser cutting, for instance, enables designers to create intricate patterns and shapes with high accuracy, while CNC milling allows for the creation of three-dimensional components with fine details. These technologies have made it easier to produce models that were once impossible or impractical to create by hand.

Materials Used in Skyscraper Models

Acrylic and Plastics

Acrylic is a popular material used in the creation of skyscraper models because it is transparent, lightweight, and easy to work with. It is often used for creating clear components such as windows, facades, and roofs. Acrylic can be easily laser-cut and shaped, making it an ideal material for intricate designs.

In addition to acrylic, other plastics such as styrene and PVC are commonly used in the construction of skyscraper models. These materials are durable, cost-effective, and easy to manipulate, making them well-suited for model making.

Foam and Cardboard

Foam is a lightweight material that is frequently used in the construction of larger-scale skyscraper models. It is easy to cut and shape, and it can be easily painted to create the appearance of different building materials, such as concrete or glass.

Cardboard, often used in combination with foam, is another popular material for creating scale models. While cardboard is less durable than foam, it is inexpensive and readily available, making it ideal for prototyping or creating simple models.

3D-Printed Components

As mentioned earlier, 3D printing has revolutionized the creation of skyscraper models. This technology allows for the creation of highly detailed components with precision, and it has become increasingly popular for producing complex and customized parts. 3D-printed models can incorporate a wide range of materials, including plastics, resins, and metals, depending on the requirements of the project.

The Future of Skyscraper Models

The Integration of AI and Machine Learning

As technology continues to advance, artificial intelligence (AI) and machine learning are expected to play an increasingly important role in the design and creation of skyscraper models. These technologies will enable architects to analyze and optimize designs more efficiently, predicting potential issues before they arise and offering solutions based on vast amounts of data.

AI can also assist in automating the creation of models, allowing for faster production and more accurate representations of the final product.

Sustainable and Green Building Models

With the growing emphasis on sustainability in architecture, skyscraper models are likely to evolve to incorporate environmentally friendly features. Architects and designers are increasingly focused on creating buildings that are energy-efficient, environmentally responsible, and sustainable. As a result, skyscraper models will likely be designed with these principles in mind, showcasing the use of renewable materials, energy-saving technologies, and green building strategies.

Conclusion: The Power of Skyscraper Models

Skyscraper models play a critical role in the world of architecture and urban design. They provide an invaluable tool for visualizing, designing, and planning these awe-inspiring structures. Through the use of various techniques and materials, designers can create detailed representations of skyscrapers that help bring their vision to life, facilitating collaboration, and refining ideas. With advances in technology, the future of skyscraper models looks brighter than ever, offering even greater possibilities for creativity and innovation in the world of architecture.