Section model architecture is an important concept in architectural design. This method involves making miniatures of buildings or structures that reveal the internal representations and relationships. More than a mere stand-alone showcase of a building that only displays the outer cover of a building, a section model exposes the interaction of all aspects inside and the organization of the spaces.

In this guide, we will go through the notion of section model architecture, the diverse technologies used to prototype these models, their importance in the process of design, as well as the cases of their application where they are irreplaceable. Whether you are an architecture student, an architect, or just a person interested in architecture, knowing section model architecture will help you understand the complex building design.

What is Section Model Architecture?

The Concept of Section Modeling

The cultural aspect of the term “section model architecture” points to the making of model according to a cutting or section of a building or structure that is real. This model enables people to see the inside of structures, the way in which they have been constructed and how their parts relate to each other, in ways beyond the obvious outside looks. The scale of a section model is usually smaller and this, therefore, allows the shared clients, designers, etc. to see and learn about the functionality of the building more profoundly.

By the way, the reason why section model architecture stands out is that it gives an architectural visualization of the spatial architectural arrangements. These entities encompass walls, columns, floors, ceilings, stairs, doors, windows, among others among the crucial elements. This is an imperative device used by architects to evaluate designs, communicate clearly visualized ideas, and so on.

Importance of Section Model Architecture

Section models are highly important for several reasons:

- Visualizing Space and Scale: Section models help to visualize the layout and organization of spaces within a building. They allow designers to understand how different spaces interact with one another, which is crucial for optimizing flow, functionality, and user experience.

- Refining Structural Elements: These models also provide a clear view of the structural components of a building. Architects can use section models to refine their designs and ensure that the building is structurally sound while meeting aesthetic and functional goals.

- Effective Communication Tool: Section models are a great way to present ideas to clients, developers, and stakeholders. They can be more engaging than 2D drawings and help to explain complex ideas in a more tangible way.

- Educational Tool: For students of architecture, section models provide hands-on experience in understanding how architectural concepts translate from paper to three-dimensional forms. They help in learning about material choices, spatial relationships, and construction techniques.

Types of Section Models in Architecture

Full Section Models

A full section model shows an entire building or structure cut along its length, height, or width. This type of model is typically used for large buildings such as skyscrapers or residential complexes. It provides a detailed view of the internal spaces and structural systems, offering a comprehensive understanding of how different elements fit together.

Full section models are generally more time-consuming and expensive to create, but they are extremely valuable for projects that require a deep understanding of both the interior and exterior of the building. These models are particularly helpful in the early stages of the design process when it is necessary to understand how the building will function as a whole.

Partial Section Models

A partial section model involves cutting through only part of the building, providing a closer look at specific areas such as a floor plan, staircase, or section of the building’s facade. Partial section models are typically used for more focused design exploration, such as when a specific floor plan or spatial arrangement needs refinement.

These models are often more cost-effective and quicker to build than full section models, and they provide detailed insights into specific parts of the building. Partial section models are especially useful when it is important to emphasize particular features or construction details.

Axonometric Section Models

Axonometric section models are a unique combination of section modeling and axonometric projection. This technique involves cutting through a building and presenting the section at an angle, allowing for a more dynamic and three-dimensional view of the structure. Unlike traditional section models, which provide a straight cut through the building, axonometric section models offer an isometric perspective, which can better represent the spatial relationships between elements.

This type of model is particularly effective for showcasing complex architectural designs, where the spatial arrangement and interplay between different building elements are critical to the overall concept.

Techniques for Creating Section Models in Architecture

Traditional Handcrafted Models

Traditionally, section models were handcrafted using materials such as cardboard, foam board, wood, and plastic. These models were created by measuring and cutting components by hand, then assembling them to form a detailed representation of the building’s interior. While this process is labor-intensive, it offers the designer complete control over the model’s quality and appearance.

Handcrafted section models often allow for a more tactile experience, which can be valuable when testing design ideas. However, the time and skill required to create these models mean they are generally more expensive and not always practical for large-scale projects.

Computer-Aided Design (CAD) and Digital Fabrication

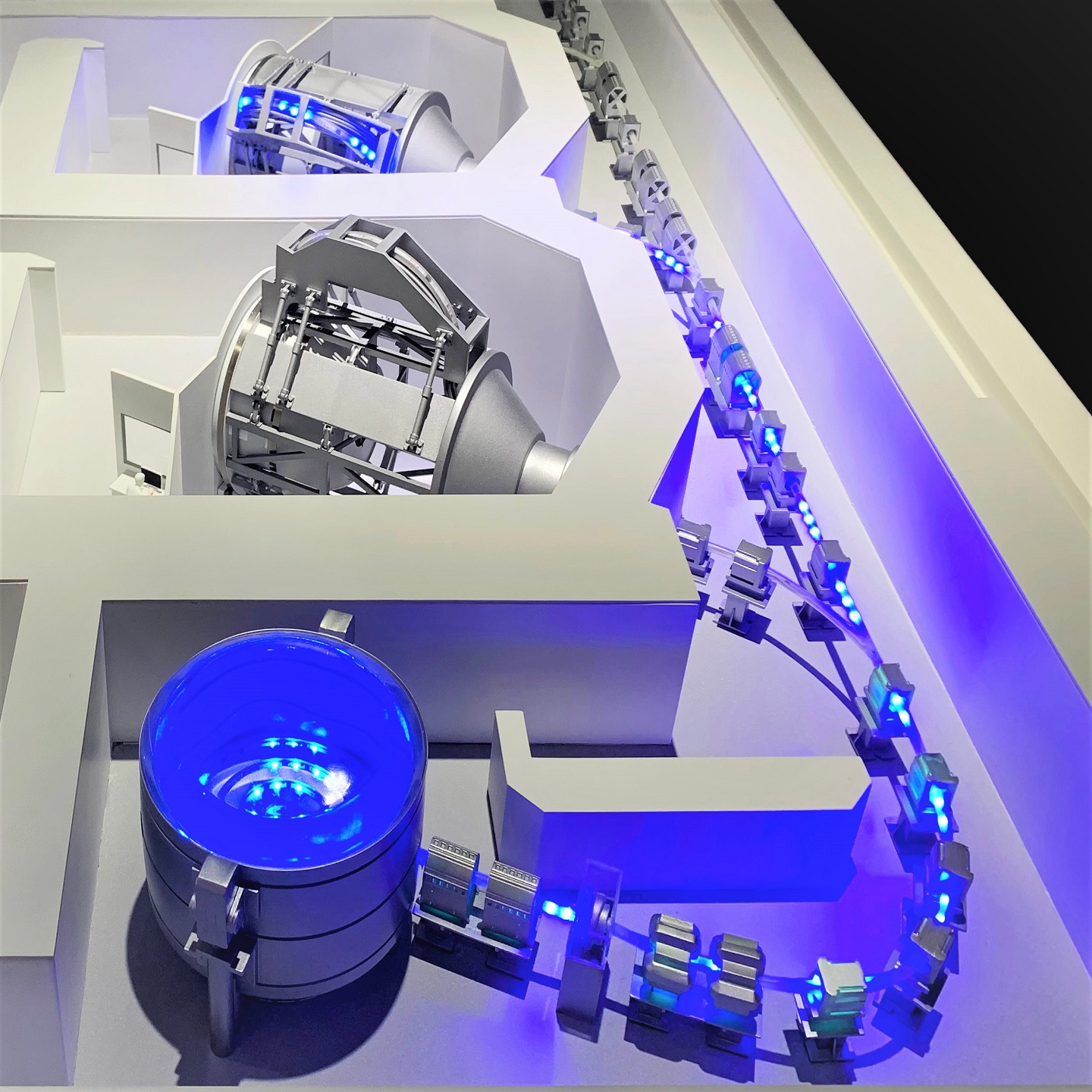

With the rise of digital technology, many architects now rely on CAD software to design their section models. CAD programs allow for highly accurate and detailed designs to be created virtually, making it easier to visualize the model and experiment with different design options. Once the model is finalized digitally, it can be fabricated using technologies such as laser cutting, 3D printing, and CNC milling.

3D printing, in particular, has revolutionized section model architecture. It allows for the creation of highly detailed and complex models quickly and efficiently. With 3D printing, architects can create models with intricate details such as windows, doors, and interior furnishings, giving a realistic and accurate representation of the building’s layout.

Laser Cutting and CNC Milling

Laser cutting is a popular technique for creating section models, especially when using materials such as acrylic, wood, or cardboard. The precision of laser cutting ensures that even the smallest components can be created with high accuracy. Similarly, CNC milling allows for the fabrication of more complex components that require detailed carving or shaping.

These technologies enable architects to create section models with a high degree of accuracy, ensuring that the models are representative of the final structure.

Materials Used in Section Models

Cardboard and Foam Board

For basic models, cardboard and foam board are commonly used due to their affordability and ease of manipulation. Foam board is lightweight yet sturdy enough for creating architectural sections, while cardboard can be easily cut and glued to form simple sections.

These materials are perfect for small-scale models or prototypes. They offer a quick and inexpensive way to explore design ideas before investing in more expensive materials.

Acrylic and Plastics

Acrylic is a popular choice for creating transparent or glossy elements in section models. It is often used for windows, walls, and other architectural components that require a sleek, polished finish. Plastics such as styrene and PVC are also commonly used for more detailed components like doors and framing elements.

These materials allow for a clean, professional finish and can be manipulated easily using digital fabrication technologies like laser cutting.

Wood and Metal

For larger and more detailed models, materials like wood and metal are used. Wood is often employed for its durability and ability to replicate building materials like timber framing and flooring. Metal elements are typically reserved for more intricate parts of the model, such as structural beams and supports.

Wood and metal are particularly useful for larger-scale models where strength and stability are important considerations.

Applications of Section Model Architecture

Enhancing the Design Process

One of the primary applications of section model architecture is in the design process. By creating detailed models of a building’s interior, architects can test different design concepts and visualize the relationships between spaces. This allows them to make adjustments to the layout, ensuring that the building functions optimally.

Section models can also help architects understand the structural and mechanical systems of a building. For example, by cutting through a building’s floors, they can gain insight into how the plumbing, electrical, and HVAC systems are arranged.

Client Presentations and Stakeholder Communication

Section models are valuable tools for client presentations and communication with stakeholders. They provide a clear, tangible representation of how the interior spaces will function, making it easier to convey design ideas and get buy-in from clients. By using section models, architects can effectively communicate how the building will meet the client’s needs and expectations.

Teaching and Learning

Section models are also used extensively in architecture education. Students often create section models to understand the principles of design and construction. The process of building a section model provides students with hands-on experience and a deeper understanding of how buildings are constructed and how various components fit together.

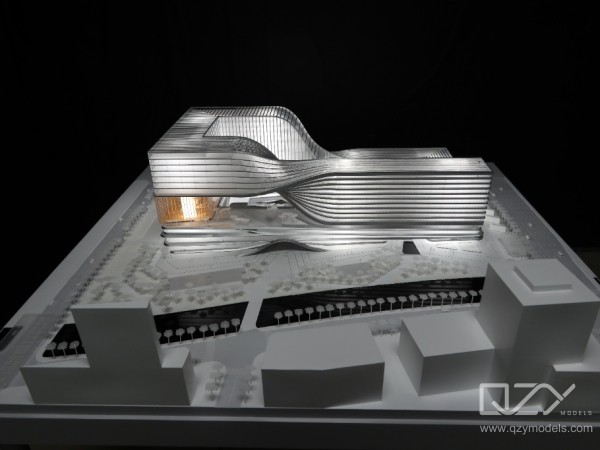

Urban Planning and Large-Scale Projects

For large-scale urban planning and master planning projects, section models are indispensable. They allow architects and urban planners to visualize how buildings will interact with the surrounding environment. By incorporating multiple section models, planners can gain insights into how different structures relate to one another in terms of scale, proportion, and urban flow.

Conclusion: The Value of Section Model Architecture

Section model architecture is an essential technique in the field of architectural design, offering a comprehensive way to explore and visualize the internal relationships of a building. These models provide an invaluable tool for refining designs, communicating ideas, and ensuring that structures function as intended. By utilizing a combination of traditional craftsmanship and modern digital technologies, architects can create highly detailed and accurate models that bring their designs to life.

Whether for educational purposes, client presentations, or the design process itself, section models are an indispensable part of the architectural toolkit, helping to transform abstract ideas into physical, tangible realities.