1. How to provide transportation and installation services for models of remote customers

QZY Models will provide a one-stop service from the production site to the installation site. The model will be sophisticatedly packaged after the initial inspection before leaving the factory and thenl be delivered to the door through the pre-determined transportation method and route. According to the budget of cost and time, we can provide air transportation (the best timeliness, but the highest price), sea transportation (cheap, but time-consuming), land transportation (the most cost-effective transportation method within 1000km), professional installation services will be offered for any location in the world to ensure the smooth installation of the model (online installation guidance or) on-site professional installation service).

2. How long does it take to make a model ?

According to the size and the degree of difficulty, the production period ranges from 1 week to 12 weeks, and the specific production period will be indicated after the production plan is determined.

3. How is the model priced?

The main factors defining model pricing include: size, proportion, lighting, base selection, landscape terrain height difference and complexity of production details, number of buildings and complexity of structures, delivery location, production period (in the case we are required to expedite the production and advance the delivery, which is much ahead of the previously determined delivery date, the price will fluctuate upward accordingly), as well as the installation method and follow-up service requirements. There is no doubt that our charges are directly related to our workload.

4. Does it matter if I am not local?

The main factors defining model pricing include: size, proportion, lighting, base selection, landscape terrain height difference and complexity of production details, number of buildings and complexity of structures, delivery location, production period (in the case we are required to expedite the production and advance the delivery, which is much ahead of the previously determined delivery date, the price will fluctuate upward accordingly), as well as the installation method and follow-up service requirements. There is no doubt that our charges are directly related to our workload.

Not at all. We manufacture models for clients all over Britain and abroad. Information exchange and client liaison is all carried out via email or telephone and regular photographs keep you in touch with progress on your model. We usually find completed models can be signed off from photographs (although you may prefer to come in for a final inspection) and there are various options for delivery.

To provide a fixed price quotation for a model, ideally we require a fairly comprehensive set of drawings but we understand this isn’t always possible. As a basic guideline, for an architectural model we would require a site plan with some indication of levels (unless it’s flat) plus several elevations of the new development. Site photographs are also very useful. For display models or exhibition models we need as many images, drawings or 3D views of the proposed design as possible. But if you are at the very early stages of a project we can supply a rough cost from very minimal information.

The information can be emailed as pdfs, dwgs, jpgs, etc. Whilst we can open most files it is usually worth a phone call to check for compatibility. If the files are very big and there are lots of them it may be worth sending them on a disc. Alternatively, if it’s just for quoting purposes, it’s always nice to receive drawings the old fashioned way, as a package of prints through the post.

A quotation is valid for a period of three months. The only part of the quotation that may change is the proposed completion date. Modelmakers has to book projects in on a first come first served basis so if there is a delay in confirming the order, other projects may well put back the date we can complete your model.

The better the information you are able to give us, the better the model we are able to give you. A full set of plans, sections, elevations and a detailed finishes schedule will enable us to make your model quickly and accurately. For architectural models in particular we need – An accurate site plan showing boundaries of model – Plan showing levels across site – Plans, elevations, sections of all buildings – Landscaping plan, if available – Any aerial or ground level photos of site. We also need references for colours of – Road treatments/ Paviours etc. around site – Main brick or cladding materials – Contrast materials – Roof finishes – Balcony & railing colours/design – Window frame colours. For more information about this please click on the “Architectural Models” link above and scroll to the bottom of the page.

Just as there is no fixed price structure for a model nor is there a standard construction time. Each model is different. A simple concept model could take just a few days. A large, complex interactive model could take five or six weeks. Most projects take somewhere in between, typically two to four weeks. However the total turn-around time will depend on our existing commitments at the time of ordering.

When planning a model the first and most important step is to establish which scale is most appropriate for the purposes of the model. This decision usually depends on two things; how big an area you need to model and how much detail you need to show. But other factors, such as, the size of your budget, how much room you will have to display the model and whether it has to be easily portable also need to be considered. Modelmakers will be happy to advise you on the pros and cons of the various scale options that most suit your project. For more detailed information about scales please click on the “Architectural Models” link above and scroll half way down the page.

Please refer to “Does it matter if I’m not local?” above.

The majority of models are made from various high grade plastics but Modelmakers has experience in working with a variety of different materials so please contact us if you have any special requirements.

Design alterations can be incorporated in your model at any point during construction but there may be a charge incurred for any abortive work already carried out. Significant alterations may also affect the completion date. However, as a gesture of good will we usually try to carry out minor changes without any additional cost or delays to the deadline.

It is not essential to come in and inspect the finished model before it is delivered although some clients prefer to do this. Other clients are happy to sign the project off using emailed photographs. We will send any views or angles you need as well as detailed close-ups of any query areas.

The options for delivery will vary from model to model. A compact one-piece model can usually be delivered by a dedicated door to door courier which is generally the lowest cost option. Larger more complex projects (such as a display model or exhibition model) will often need to be delivered by our own staff, especially if the project requires careful setting up or an element of demonstration. Models for export will usually require a purpose-built flight case which is a service we provide. Modelmakers will usually give an indication of the likely delivery arrangements in the quotation process.

We are frequently asked to repair or update models made by other companies who are either no longer trading or are too far away to be cost effective for minor amendments. Please feel free to contact us for a quotation regarding any work on an existing model you may have.

This depends on the size of the model and where you are intending to display it. Smaller models can be displayed on any desk or suitably sturdy table. For larger models we can provide either a purpose built plinth or removable legs. We can offer a wide variety of designs and materials.

We supply all architectural models with a sturdy Perspex cover to protect them from dirt and damage. We can repair Perspex cases or supply new ones to any dimensions you require.

We pride ourselves on our Global Model Shipping and Installation Services, which ensure that your models are delivered safely to any city around the world. With over 20 years of experience in this field, we have honed our processes to provide a seamless and efficient service tailored to meet the specific needs of each project.

Comprehensive Shipping Solutions

Our extensive experience encompasses every aspect of the shipping process, including:

Expert Packaging: We utilize specialized packaging techniques to protect models during transit, ensuring they arrive in perfect condition. Our packaging is designed to meet the requirements of various transportation methods and the specific dimensions of each model.

Transportation Logistics: We carefully select transportation methods based on the nature of the model and its destination, considering factors such as budget, timing, and the most efficient route. We ensure that transportation aligns with the packaging size and requirements for safe handling.

Customs Compliance: Our team is well-versed in the import/export regulations of different countries. We handle all necessary documentation to facilitate smooth customs clearance and compliance with local laws, mitigating any potential delays or complications.

Climate Adaptability: We evaluate whether models are suitable for local climate conditions, ensuring that materials and finishes can withstand environmental factors in the destination city.

Professional Installation and Maintenance

In addition to shipping, we offer professional installation services that guarantee your models are set up correctly and functionally in their intended locations. We also provide ongoing support and maintenance, regardless of whether the models were produced by us or other manufacturers:

Thorough Inspection: We conduct comprehensive inspections of models upon arrival to ensure they meet quality standards and are free of any damage.

Maintenance and Repair: Our skilled technicians are equipped to perform routine maintenance, repairs, and refurbishments on models, acting as the “family doctor” for your models. No matter the issue, we are committed to restoring them to their best condition.

Adaptability to Local Practices: We take into account regional differences in model upkeep and care, providing tailored recommendations for maintenance based on local practices and environmental considerations.

Your Trusted Partner

At QZY Models, we understand that every detail matters in the shipping and installation process. Our commitment to quality service means we never shy away from challenges—no matter how complex the model or the issues at hand, we are here to ensure that your models look their best and perform optimally.

With QZY Models, you can rest assured that your models are in expert hands, backed by decades of experience and a dedication to excellence.

We offer comprehensive 3D printing services, including file design optimization, physical model printing, and post-processing services such as sanding and painting. Our 3D printing capabilities allow us to produce detailed and accurate models quickly and efficiently, with a wide variety of materials to meet the specific needs of your project.

Advantages of 3D Printing

Complex Shapes: One of the key benefits of 3D printing is its ability to create highly complex and intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This makes it ideal for producing intricate architectural models, sculptures, and industrial components.

Fast Turnaround: 3D printing can significantly reduce production time. Once the design is finalized, we can quickly move from concept to finished model, providing faster delivery compared to other techniques like CNC machining or handcrafting.

Cost-Effective: For small runs or prototypes, 3D printing is generally more cost-effective than other manufacturing methods, especially when dealing with complex designs that would require expensive molds or tooling in traditional fabrication.

Versatility of Materials: We offer a wide range of materials to suit different needs, including transparent, semi-transparent, and white resins, as well as ceramics, metals, red wax, and nylon. Each material has its unique properties, such as varying degrees of hardness, flexibility, and durability, providing greater flexibility in model creation.

Material Options: 3D printing supports a variety of materials, including:

Transparent and semi-transparent resins

Ceramics for more rigid and heat-resistant models

Metal for industrial-grade models

Nylon for durable and flexible prints

Red Wax for precision casting molds

Other Specialty Materials like white resin for detailed models

Disadvantages of 3D Printing

While 3D printing has many benefits, it does come with certain limitations:

Material Degradation: Some materials, especially those used for prototypes, can be prone to discoloration or deformation over time, especially when exposed to heat, light, or humidity.

Limited Surface Finishing: Certain materials used in 3D printing do not accept paint or other finishing treatments well, which can limit their use for final presentation models without additional post-processing.

Lower Precision: Although 3D printing is highly accurate for most applications, it has slightly lower precision compared to laser cutting or CNC machining, particularly in terms of fine details and surface smoothness.

Post-Processing Required: Most 3D-printed models require additional work after printing, such as sanding, polishing, or painting, to achieve the desired finish and smooth out imperfections.

Applications of 3D Printing

Our 3D printing services can be applied across various industries, including:

Architectural models

Industrial prototyping

Product design

Medical devices

Creative sculptures

Exhibition pieces

At QZY Models, we leverage the flexibility and efficiency of 3D printing to provide high-quality models tailored to your specific requirements. Our team can also assist in optimizing your 3D printing files for better results, ensuring the final product meets your design goals.

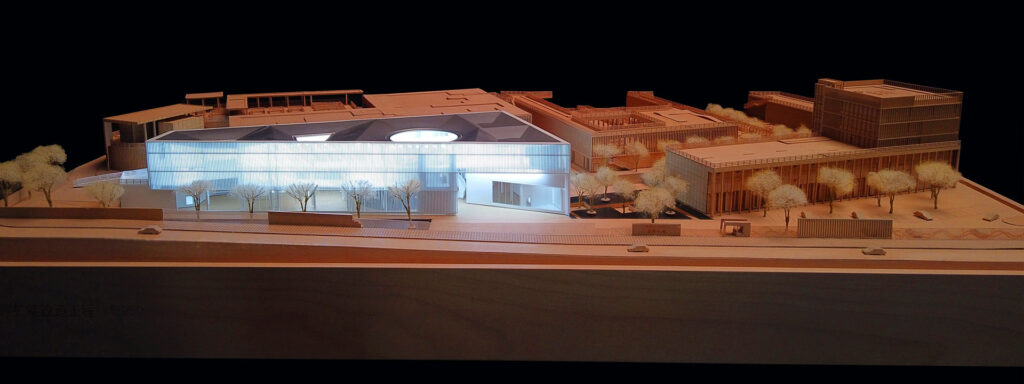

Our core expertise lies in crafting Custom High-end Architectural Models that transcend conventional techniques, materials, and forms. We specialize in delivering unique, tailored solutions that align with the creative visions of our clients. Our approach is driven by a deep understanding of the design intent, allowing us to create models that go beyond mere representation—they capture the essence and meaning of the architecture itself.

We believe that every design holds an underlying narrative, and our skilled team excels at interpreting and expressing this narrative through innovative modeling techniques. By closely collaborating with architects and designers, we ensure that the final model not only serves as a visualization tool but also acts as a source of inspiration, revealing new perspectives and highlighting the elegance and beauty that might otherwise remain unseen.

Our custom models are designed to amplify the architectural impact, bringing out the individuality, tension, and personality of each project. Whether you require a model for a cutting-edge skyscraper, a cultural landmark, or a visionary urban development, we are committed to delivering solutions that push creative boundaries. Our models are more than just physical representations—they are works of art that communicate the spirit of the design.

By utilizing advanced materials, state-of-the-art technology, and unconventional craftsmanship, we ensure that each model is meticulously crafted to meet the highest standards of quality and precision. Our innovative approach allows us to explore new methods and materials that best reflect the design’s unique character and purpose, providing clients with models that are both functional and aesthetically captivating.

Our expertise goes beyond architectural models. We offer comprehensive fabrication services for a wide range of physical models tailored to various industries and purposes. Our team specializes in creating precise, scaled-down models that bring concepts and designs to life, providing visual clarity and technical accuracy for diverse applications. These models are valuable tools for presentations, demonstrations, prototypes, and exhibitions. Our model categories include, but are not limited to:

Landscape Models: Capture outdoor environments with detailed representations of parks, green spaces, urban planning, and natural features.

Interior Design Models: Showcasing interior decoration designs, sectional structure designs, and spatial designs, providing detailed displays of interior environments.

Signage & Sculptures: Custom-made models for signage, artistic sculptures, and branding elements.

Industrial Models: Scaled-down versions of industrial equipment, machinery, and production lines for presentations, training, and technical demonstrations.

Mechanical & Engineering Models: Represent complex mechanical systems and construction processes in an easy-to-understand format.

Gift & Promotional Models: Unique and creative physical models for corporate gifts, promotional items, and special events.

Medical Device Models: Highly detailed replicas of medical equipment and devices used for demonstrations, training, and exhibitions.

Energy Equipment Models: Models of energy infrastructure, including renewable energy setups, power plants, and equipment, for industrial use.

Transportation Infrastructure Models: Scaled models of transport systems, including vehicles, stations, airports, and railway facilities.

Topographic & Terrain Models: Detailed geographic and topographic models for land development, environmental studies, and educational purposes.

Hydraulic & Water Facility Models: Representations of water management systems, including dams, water treatment plants, and irrigation systems.

Military Models: Models of military equipment, vehicles, aircraft, and naval vessels for research, education, and exhibitions.

Engineering Vehicles, Aircraft & Ships: Scaled replicas of construction vehicles, aircraft, and ships used in industrial and educational displays.

Figurine & Animal Sculptures: Realistic and stylized models of humans, animals, or other characters for museums, exhibitions, and creative displays.

Whether you need a detailed representation of industrial equipment, a landscape design, or a precise medical device model, we ensure each project is custom-tailored to match your exact specifications. Using advanced fabrication techniques, including 3D printing, CNC machining, and laser cutting, we deliver models that meet the highest standards of quality and accuracy.

Our models are designed to support a variety of industries, providing practical solutions for demonstration, training, project development, and marketing. We work closely with our clients to ensure every detail is captured, from material selection to scaling and finishing, creating physical models that are as functional as they are visually impressive.

我们提供全面的设计解决方案,通过精湛的工艺和尖端技术将您的愿景变为现实。我们的团队擅长制作定制模型设计,以满足每个项目的独特需求,无论是建筑展示、城市规划、展览还是开发展示。

专业工艺:我们经验丰富的专业人员将您的想法转化为细致的模型,确保每个项目的精确度和质量。

材料灵活性:我们提供多种材料选择,包括木材、丙烯酸和 3D 打印组件,以适应各种建筑风格和设计偏好。

创新技术:利用先进的 3D 打印和激光切割技术,我们确保每个模型的细节复杂而精确,即使是最复杂的设计也能提供高质量的结果。

项目类型的多样性:无论是住宅建筑、商业综合体、城市开发还是展览模型,我们都会调整方法来满足每个项目的独特需求。

我们对创新和质量的承诺确保我们设计的每个模型都与您的愿景完美契合,使您的项目脱颖而出并留下持久的印象。