Model-making is an art that demands a diverse set of skills, ranging from technical precision to creative ingenuity. These essential skills empower model-makers to transform abstract concepts into tangible representations that captivate and inspire. In this comprehensive guide, we delve into the fundamental skills that every aspiring model-maker should master. From precise measurement and expert material selection to innovative techniques and creative problem-solving, this exploration will equip you with the expertise to create awe-inspiring models that transcend the boundaries of imagination.

I. Precision in Measurement and Scaling

The art of model-making demands a keen eye for detail and a mastery of precise measurement and scaling techniques. In this crucial part of the process, model-makers delve into the world of accurate measurements and meticulous scaling to bring their visions to life. From understanding the intricacies of different scaling ratios to employing an array of measurement tools.

A. Accurate Measurement Techniques:

Precise measurement is the cornerstone of successful model-making. Mastering various measurement tools, such as rulers, vernier calipers, and micrometers, enables model-makers to capture intricate dimensions with impeccable accuracy. Whether constructing architectural landmarks or intricate mechanical components, the ability to measure with precision ensures that the final model aligns perfectly with the intended design.

B. Grasping the Art of Scaling:

Understanding scale ratios and applying them effectively is a fundamental skill for model-makers. Scaling allows them to accurately downsize or upscale real-world objects while maintaining accurate proportions. This skill is particularly crucial when creating models for projects with diverse scales, from large-scale urban developments to miniature dioramas.

II. Material Selection and Handling

This section delves into the artistry of material selection and the adept handling required in model-making. From traditional mediums like wood, paper, and clay to cutting-edge options like 3D-printed components, model-makers navigate diverse materials to craft impeccable models. Understanding material characteristics and their impact on the design is crucial, as it ensures every stroke, cut, and adhesion is executed with precision, resulting in a visually stunning and functional masterpiece.

A. Exploring Materials:

Model-making encompasses a vast array of materials, each offering unique properties and characteristics. Expert model-makers familiarize themselves with an extensive range of materials, such as balsa wood, styrene, acrylic, resin, and metal. This knowledge enables them to select the most appropriate materials for different components of the model, considering factors like strength, weight, texture, and ease of manipulation.

B. Skillful Material Handling:

Working with various materials demands skillful craftsmanship. Model-makers employ a multitude of techniques, such as cutting, sculpting, bending, and molding, to shape the materials into the desired forms. Additionally, mastering bonding methods, like gluing, welding, and soldering, ensures that the model remains structurally sound and visually cohesive.

C. Incorporating Sustainable Practices:

With sustainability becoming a global priority, model-makers are embracing environmentally friendly practices. They seek out eco-conscious materials, utilize recycled elements, and adopt waste reduction strategies. This commitment to sustainability not only benefits the environment but also resonates with clients and stakeholders who prioritize green initiatives.

III. Craftsmanship and Attention to Detail

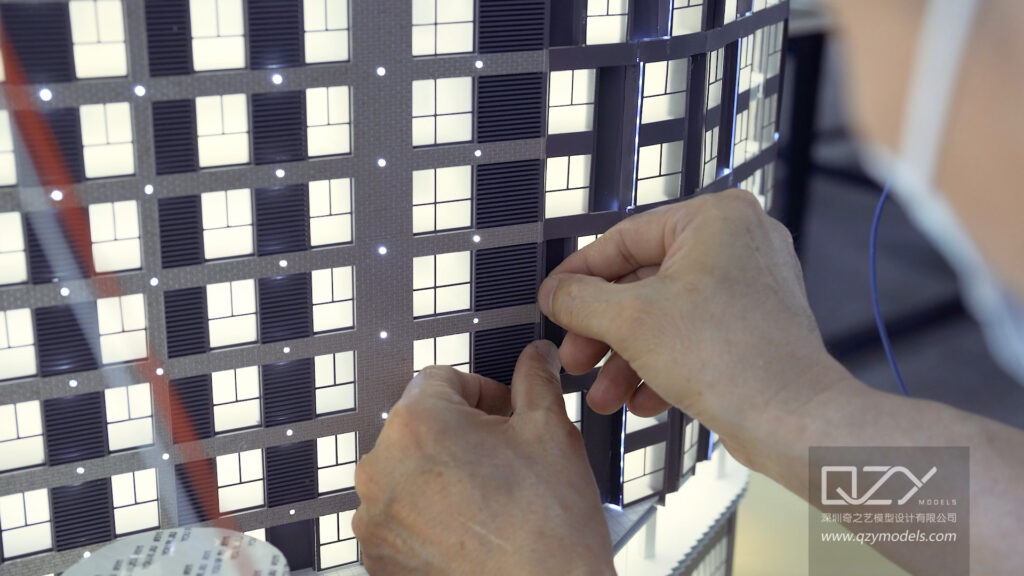

This section delves into the art of model-making, emphasizing the importance of craftsmanship and attention to detail. Each model crafted by skilled artisans reflects their passion and commitment to precision. From replicating textures to handcrafting delicate features, model-makers demonstrate their unwavering dedication, creating awe-inspiring models that capture the essence of the original design.

A. Refining Artistic Craftsmanship:

Model-making is not just a technical pursuit; it requires an artistic eye for detail. Meticulous craftsmanship allows model-makers to create intricate textures, replicate fine finishes, and incorporate lifelike elements into their models. The artistry elevates the models from functional representations to breathtaking works of art.

B. Utilizing Textures and Finishes:

Model-makers understand the significance of textures and finishes in making a model visually compelling. Whether simulating the weathered patina on historical structures or creating smooth, polished surfaces on modern designs, skilled model-makers utilize various techniques to add depth, realism, and visual interest to their models.

C. Emphasizing Aesthetics and Presentation:

An aesthetically pleasing presentation is crucial for captivating audiences and effectively communicating ideas. Model-makers skillfully use color palettes, lighting effects, and thoughtful composition to accentuate the model’s features, ensuring that it leaves a lasting impression on viewers.

IV. Innovation and Problem-Solving

A. Creative Problem-Solving:

Model-making often involves overcoming complex challenges. Innovative thinking allows model-makers to find creative solutions for design intricacies, structural stability, and the integration of diverse elements. Resourcefulness and adaptability are key traits that enable them to navigate unexpected obstacles and deliver outstanding results.

B. Embracing Digital Technology:

The advent of digital technology has revolutionized the model-making landscape. Model-makers proficient in CAD software, 3D printing, laser cutting, and virtual reality techniques have the advantage of pushing the boundaries of creativity and precision. These tools empower them to craft intricate models that were once considered impractical or impossible.

V. Communication and Collaboration

A. Effective Communication:

Clear communication is vital for successful model-making projects. Model-makers must effectively articulate their ideas, understand client requirements, and engage in open dialogue with stakeholders. Strong communication skills foster a collaborative atmosphere where all parties work cohesively towards a shared vision.

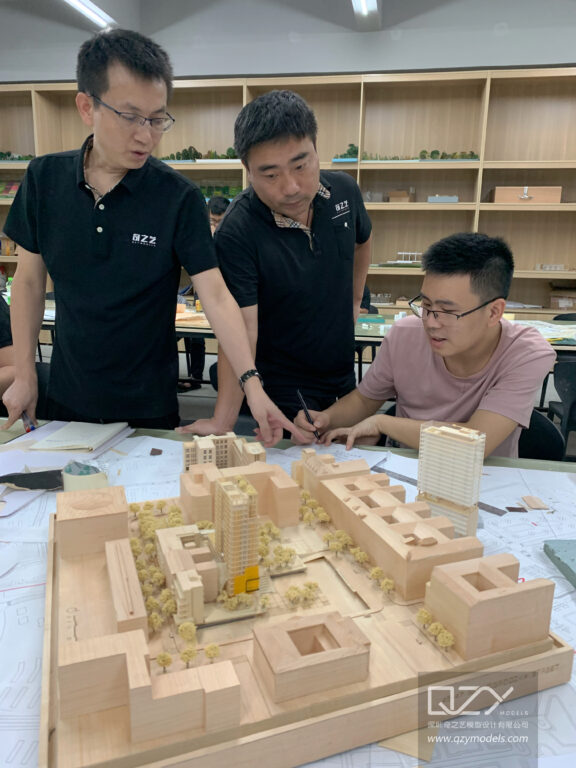

B. Collaborative Teamwork:

Model-making often involves teamwork, with model-makers collaborating with architects, designers, engineers, and other specialists. Thriving in collaborative environments requires adaptability, active listening, and the ability to contribute constructively to group dynamics. A cohesive team can synergize talents and expertise to create comprehensive and exceptional models.

Mastering the craft of model-making is a multi-faceted journey that demands a diverse skill set. Precision in measurement and scaling ensures accurate representations, while adept material selection and handling allow for the seamless creation of intricate models. The fusion of craftsmanship and attention to detail elevates models to artistic masterpieces, while innovation and problem-solving enable model-makers to overcome challenges and explore new frontiers. Effective communication and collaborative teamwork complete the skill set, empowering model-makers to bring their visions to life and create awe-inspiring models that stand as tangible testaments to their expertise and passion. As model-makers embrace continuous learning and embrace the artistry in three dimensions, their creations will continue to inspire, captivate, and shape the world around them.

Discovering the World Through Miniatures – About Us

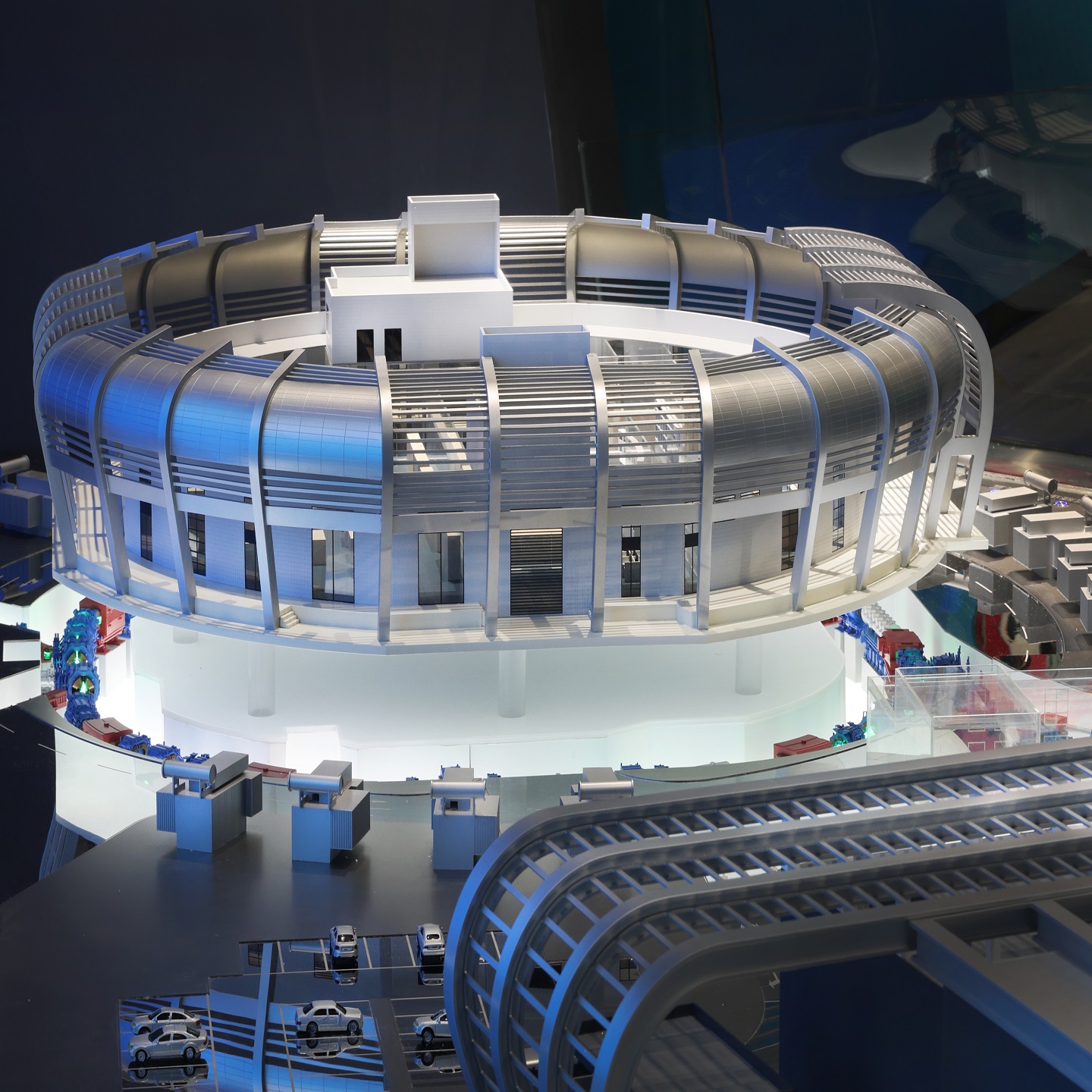

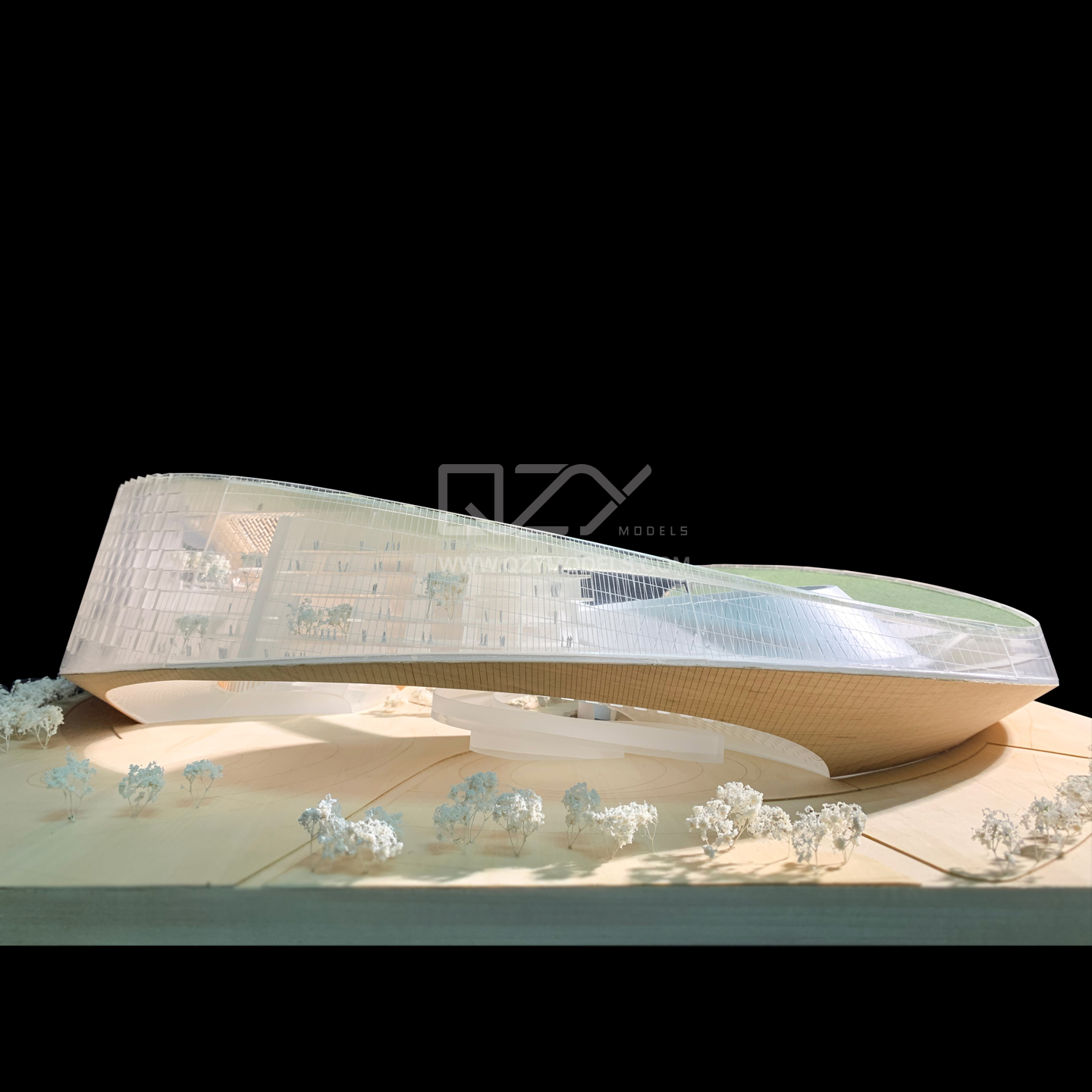

QZY Models, founded in 2013 in Shenzhen, China, is a leading professional team specializing in the design and production of customized physical models. Rooted in the architecture industry, QZY Models caters to diverse model production needs, ranging from furniture, interior design, architectural landscape, to urban planning. Moreover, we are continuously exploring various fields, including dynamic mechanical models, industrial equipment displays, scientific and technological principle displays, and exhibition displays, to create a diverse model service ecosystem.

Since commencing our independent business in 2013 and establishing our base in Shenzhen, ensuring quality has always remained our top priority. We have forged strong collaborations with renowned companies in over ten countries, such as the United Kingdom, the United States, Canada, and Singapore. Our completed projects span across China, the United Arab Emirates, Saudi Arabia, Egypt, Poland, Morocco, Ethiopia, and other countries. Presently, QZY Models has established branches or offices in Egypt, Morocco, Saudi Arabia, Lebanon, Italy, the Netherlands, and other locations, firmly committed to serving global customers.For more information, please visit our official website: www.qzymodels.com