The craftsmanship embedded in wooden model making is steeped in tradition. Artisans, wielding time-honored tools, intricately carve, shape, and assemble components with an artistry that resonates across generations. The choice of wood becomes an art in itself, with artisans meticulously selecting species based on grain patterns, densities, and workability. In the delicate dance between creativity and precision, wooden model-making emerges as an art form that transcends time and technology. The tactile warmth of wood, the meticulousness of traditional craftsmanship, and the versatile applications of these handcrafted marvels make this age-old practice a fascinating journey into the heart of artistry. This article embarks on an exploration of the nuanced world of crafting wooden models, delving into the purpose, techniques, and enduring charm that emanate from these finely honed creations.

I. The Purpose and Significance of Wooden Model Making

A. Architectural Prototyping:

Wooden models play a pivotal role in architectural prototyping, providing architects and designers with tangible representations of their visions. Architects can scrutinize spatial relationships, assess design concepts, and identify potential challenges before groundbreaking begins, contributing to the seamless execution of architectural projects.

B. Educational Tools:

Wooden model making serves as an indispensable educational tool, particularly in architectural and design programs. Students engage in hands-on learning, refining their skills in scaling, detailing, and understanding spatial relationships. This tactile experience enriches their education, bridging theoretical knowledge with practical application and fostering a deeper appreciation for craftsmanship.

II. Techniques and Methodologies in Wooden Model Making

A. Traditional Craftsmanship:

Rooted in tradition, wooden model making relies on time-honored craftsmanship. Skilled artisans meticulously carve, shape, and assemble individual components using hand tools such as chisels, knives, and saws. This traditional approach preserves the authenticity and artistry inherent in this age-old craft.

B. Wood Selection and Grain Considerations:

The choice of wood is critical in wooden model making, influencing both structural integrity and aesthetic appeal. Artisans meticulously select wood species based on characteristics such as grain pattern, density, and workability. Understanding how different woods respond to carving and shaping ensures a harmonious balance between artistic vision and material properties.

III. Detailing in Wooden Models

A. Carving and Relief Work:

The art of carving takes center stage in wooden model making, allowing skilled artisans to breathe life into their creations. Intricate designs, textures, and architectural details emerge through the careful removal of wood. Relief work, where elements are raised above the base, adds a three-dimensional quality, creating visually stunning and realistic models.

B. Finishing and Surface Treatments:

Elevating wooden models to refined states involves meticulous finishing touches. Artisans apply various surface treatments such as staining, painting, or varnishing to enhance the natural beauty of the wood and emphasize specific details. The choice of finish becomes an artistic decision, contributing to the overall aesthetics of the model.

IV. Applications and Charm of Wooden Models

A. Historical Reproductions:

Wooden models find applications in reproducing historical structures with unparalleled accuracy. Whether recreating the intricate details of ancient temples or meticulously showcasing historical buildings, these models serve as tangible links to the past, preserving architectural heritage with unwavering precision.

B. Artistic Expressions:

Beyond architectural replication, wooden model making offers a canvas for artistic expression. Artists and craftspeople leverage the medium to create sculptures, abstract forms, and artistic representations, showcasing the versatility of wooden models as intricate works of art.

V. Challenges and Considerations in Wooden Model Making

A. Material Limitations:

While wood provides a warm and natural aesthetic, it does pose certain limitations in representing intricate details compared to materials like plastic or resin. Model-makers navigate these challenges creatively, leveraging the inherent beauty of wood while acknowledging its constraints.

B. Preservation Challenges:

Preserving wooden models presents challenges, especially when exposed to environmental factors. Implementing proper storage, finishing techniques, and climate control measures is crucial to ensure the longevity of these handcrafted creations.

VI. Contemporary Innovations in Wooden Model Making

A. Integration of Technology:

Contemporary wooden model makers integrate technology to enhance precision and efficiency. Computer-aided design (CAD) software, laser cutting, and CNC machining contribute to intricate detailing while preserving the authenticity of handcraftsmanship.

B. Hybrid Approaches:

Modern artisans adopt hybrid approaches, combining traditional woodworking techniques with cutting-edge technologies. This fusion allows for the warmth of handcrafted wooden models coupled with the precision afforded by digital tools.

VII. Sustainable Practices in Wooden Model Making

A. Responsible Wood Sourcing:

Sustainability takes center stage in wooden model making, with an increasing emphasis on responsible wood sourcing. Opting for sustainably harvested or reclaimed wood aligns with eco-friendly practices, ensuring the craft remains environmentally conscious.

B. Waste Reduction and Recycling:

Wooden model makers actively seek ways to minimize waste and promote recycling. Innovative approaches to repurpose wood scraps and reduce material waste during crafting contribute to sustainable practices within the craft.

In the delicate intersection of tradition and innovation, wooden model making stands as a testament to the enduring beauty of craftsmanship. From its roots in architectural prototyping to its metamorphosis into a canvas for artistic expression, the artistry of wooden models thrives in the hands of skilled artisans. As we navigate the challenges of material limitations and embrace contemporary innovations, the heart of this craft remains tethered to the warmth of wood and the timeless dance between tradition and modernity. The legacy of wooden model making, with its tactile allure and artful precision, continues to weave a narrative that transcends generations, preserving not just structures but the very essence of craftsmanship itself.

Discovering the World Through Miniatures – About Us

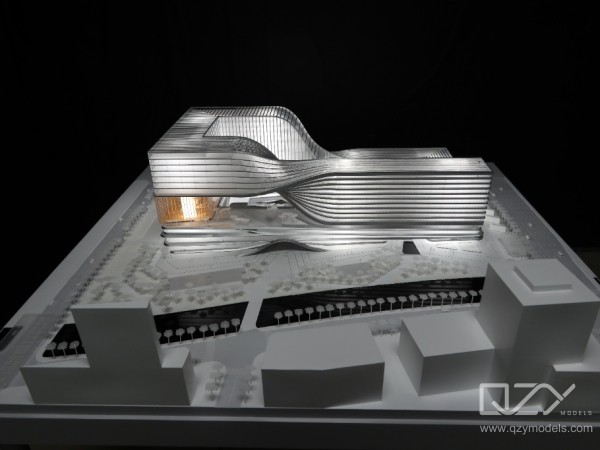

QZY Models, founded in 2013 in Shenzhen, China, is a leading professional team specializing in the design and production of customized physical models. Rooted in the architecture industry, QZY Models caters to diverse model production needs, ranging from furniture, interior design, architectural landscape, to urban planning. Moreover, we are continuously exploring various fields, including dynamic mechanical models, industrial equipment displays, scientific and technological principle displays, and exhibition displays, to create a diverse model service ecosystem.

Since commencing our independent business in 2013 and establishing our base in Shenzhen, ensuring quality has always remained our top priority. We have forged strong collaborations with renowned companies in over ten countries, such as the United Kingdom, the United States, Canada, and Singapore. Our completed projects span across China, the United Arab Emirates, Saudi Arabia, Egypt, Poland, Morocco, Ethiopia, and other countries. Presently, QZY Models has established branches or offices in Egypt, Morocco, Saudi Arabia, Lebanon, Italy, the Netherlands, and other locations, firmly committed to serving global customers.

For more information, please visit our official website: www.qzymodels.com