Introduction to Architecture Model Materials

Architectural model making is an indispensable part of the design process in the world of architecture. For architects, students, and professionals alike in the field of design, it is important to understand the different architectural model materials to produce accurate, functional, and visually compelling models. These models serve a variety of purposes, ranging from conceptual exploration to client presentations and final showcase pieces. Choosing the right material for your architecture model is fundamental in communicating design ideas clearly and effectively.

In this article, we look at what modeling materials are commonly used in making architectural models, the pros and cons of different varieties, and how to choose the best one to meet the particular needs of your project. From 3D modeling materials to scale model building materials, we will also explore how various modeling materials can enhance the overall design experience.

Different Types of Architecture Model Materials and Their Purposes

Before going into details regarding each architecture model material, it is essential to understand the types of models architects create and the purposes they serve. The models can vary from very basic conceptual models to highly detailed final showcase models that are supposed to impress the clients or win competitions.

Conceptual Architecture Models

Conceptual models are generally made at the very beginning of the design process. They are used to investigate the general form and mass of a design and often emphasize spatial relationships rather than details. The purpose of a conceptual model is to convey an idea about the volume and layout of a building in a simple, clear way.

Materials for conceptual architecture models are most of the time lightweight and easy to handle. The concentration is on the general form; therefore, it’s not a concern for fine detailing. Accessibility, ease of cutting, and cost-effectiveness make foam boards, modeling foam, and cardboard staple materials during this stage. In creating conceptual models, the popular material used is polystyrene foam since it allows rapid manipulation of parts for quick changes and rapid prototyping.

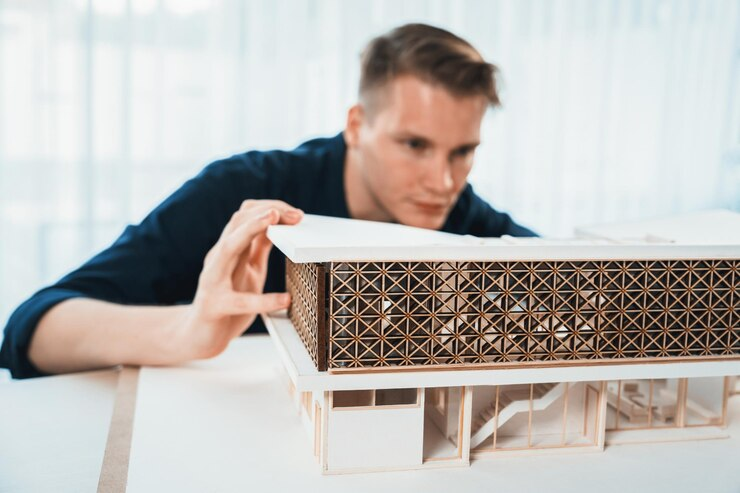

Presentation Architecture Models

Presentation models are usually those models first exposed to clients, investors, or wider audiences. The presentation models represent a more advanced stage of the design compared to conceptual models; however, they may also not include all the minute details. Their purpose is to visually communicate the design in a way that conveys materiality, massing, and spatial organization.

In the case of presentation architecture models, acrylic or plexiglass can be used for glazing and window elements to simulate transparency. More refined materials, such as wood or polystyrene foam, can be used for the structure of the building. For detailing, metal sheets of aluminum or brass might be employed, while natural materials like sand or pebbles can be used for landscaping elements. It must result in a model having an increased level of information while being easy to comprehend from the viewer’s standpoint.

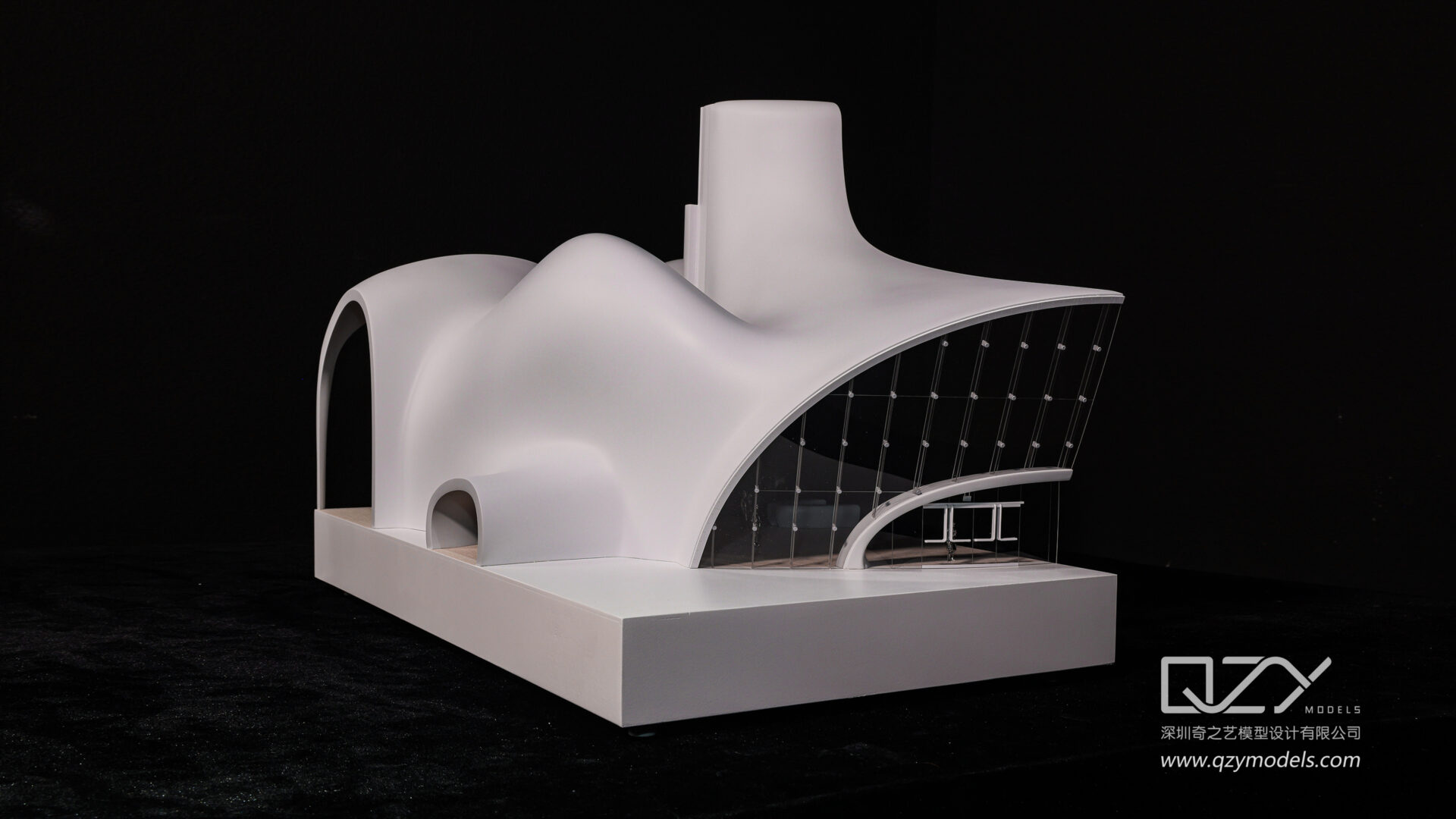

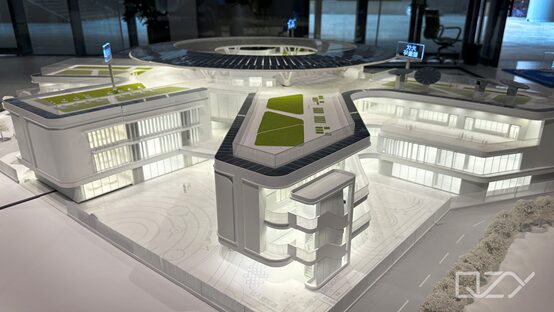

Final Showcase Architecture Models

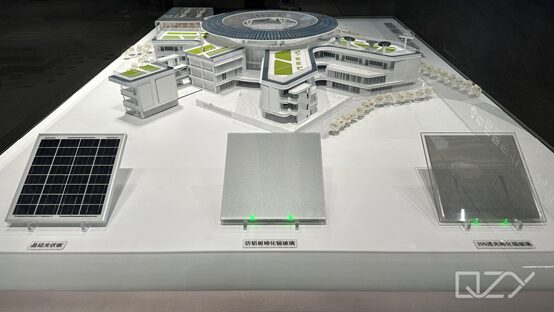

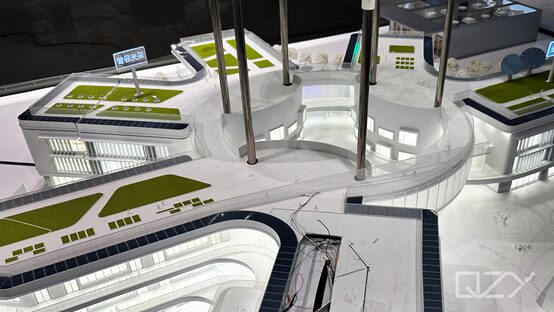

Final showcase models are the most detailed models and are normally used for competitions, final presentations, or public exhibitions. These models need to be very accurate and impressive in appearance and often are exact in material, texture, and scale that will be found on the completed building. They can be larger or smaller physically, but they are detailed to include every aspect of the design.

For these final models, a combination of premium model materials is often used. These could include acrylic for transparent features, wood for structural detailing, and metal sheets for roofing or façades. High-quality modeling foams are used for shaping and surface smoothing. Polystyrene foam, in conjunction with detailed handcrafting, often makes up the bulk of the model’s volume, though other materials can be used to create intricate detailing.

Key Architecture Model Materials and Their Best Uses

Selecting the proper architecture model materials is required for achieving the desired aesthetic and functional goals of the project. Here’s a breakdown of several of the most commonly used model materials in architectural model making and their best uses.

Foam Boards

Among the most used materials for architectural model making, of course, are the different types of foam boards with their lightweight, versatile natures, and ease of manipulation. These boards have been made of a foam core sandwiched between two layers of paper, hence just ideal for cutting, shaping, and gluing. Probably, the most commonly employed in conceptual and presentation models, where speed and simplicity of execution are imperative, are foam boards.

Best Use: Conceptual architecture models, rapid prototyping, simple massing models.

Transparent Materials (Acrylic/Plexiglas)

Transparent materials like acrylic and plexiglass are also common in presentation architecture models to simulate windows, glazing, and other transparent architectural elements. These can be laser-cut or hand-processed and are clear to simulate glass elements or clear facades. They provide the added ability to showcase the model from different angles without losing the clarity of interior spaces.

Best Use: Presentation models, windows, facades, and glazing elements.

Cardboard and Plywood

Cardboard and plywood are two very cheap, accessible materials that have generally been used in architectural model making. The cardboard is excellent to be used in conceptual models due to its ease of being cut and manipulated but cannot provide the strength and quality for a high-quality presentation. On the other hand, plywood can add a more solid and durable structure to models and can be used for final showcase models, particularly when a more organic or industrial look is desired.

Best Use: Conceptual models, structural detailing, affordable building elements.

Wood

Wood is one of the most traditional materials used in architectural model making. It has both aesthetic appeal and durability, making it ideal for presentation models and final showcase models. Wood can be carved, sanded, and shaped into detailed elements such as facades, columns, beams, and even flooring. In addition, wood can be stained or painted for different finishes, offering versatility in design.

Best Use: Presentation models, detailing, textures, and finishes.

Polystyrene and Modeling Foam

Polystyrene foam is widely used in architectural model making because it offers great versatility, a smooth finish, and ease of cutting. It can be shaped quickly and then painted to create smooth, clean surfaces for both conceptual and final showcase models. Modeling foam is available in a variety of densities and can be used for everything from simple massing to intricate detailing.

Best Use: Conceptual models, final showcase models, terrain, and volumetric forms.

Metal Sheets (Aluminum, Copper, Brass)

Detailed architectural features can be made from these metal sheets, such as roofing, facades, or sculptural elements, by using aluminum, copper, and brass. Most of the final showcase models use these metals due to their realistic appearance in imitating the actual model construction materials. Metals lend an industrial or modern touch to the model.

Best Use: Final showcase models, roofing, facades, and intricate detailing.

Enhancing Realism with Surrounding Elements

In creating an architectural model, it is not always the building that a modeler needs to be concerned with. Peripheral elements such as landscape features, scale figures, and outdoor fixtures can greatly enhance the realism and effect of the model.

Landscape and Natural Elements

To add some realism to the model, landscape elements like trees, grass, shrubs, and soil can be used. These are usually created from natural materials such as moss, real sand, or synthetic turf. Also, wire and foliage trees made to scale can be used to simulate greenery and give depth to the surroundings of the model.

Scale Figures and Vehicles

Scale figures and vehicles can bring an architectural model to life. They provide viewers with a more personal understanding of the human scale of the project. These miniature figures are available for purchase through specialized model-making suppliers or can be handmade. They give it that personal touch, which would help to better imagine people’s interactions with the space.

Street Furniture and Outdoor Fixtures

Adding street furniture such as benches, lamps, and trash bins can give an extra depth of realism to your architectural model. These elements contribute to the atmosphere and can help emphasize the functionality of outdoor spaces. Usually, they are made from materials on a small scale, mainly plastic, metal, or resin.

Practical Tips for Material Selection

However, this selection may at times pose a challenge when a compromise between budget and quality or other practical aspects comes up. Here are some very practicable model material selection tips in that regard:

Balance Budget versus Quality

It’s important to balance your budget with the quality of materials used. High-end materials like acrylic, metal sheets, and premium modeling foam can elevate your model’s quality but might come at a higher cost. On the other hand, materials like cardboard and foam boards can be more affordable, though they may not provide the same level of detail. Choosing the right material depends on the purpose of the model and the available resources.

Consider Durability and Transport Needs

If your model needs to be transported or will be handled frequently, durability is an essential factor to consider. Wood and metal sheets tend to be more durable than foam boards or cardboard. When presenting models in public settings, durability, and portability should be prioritized to prevent damage.

Ease of Assembly and Detailing

Depending on the desired resolution, select materials that will allow for ease of assembly and detailing. For instance, polystyrene foam is great for carving and painting fine details, while acrylic allows for precise cuts and clear, smooth surfaces.

Final Thoughts

The type of architecture model materials selected greatly influences the outcome of a project, be it for conceptual exploration, client presentation, or final showcase. Knowing the properties, advantages, and limitations of various model materials will help you to make a model that best communicates your design intent while meeting your practical needs. From the use of foam boards for basic models to acrylics and metal sheets for more sophisticated presentations, each material has its place in architectural model making.

As you refine your model, there needs to be a fine balance between aesthetics and functionality, taking into consideration the appearance, durability, ease of assembly, and transport. Whether working with 3D modeling materials or handmade crafting techniques, selecting an appropriate architectural model material is important in giving elegance to the model and will help to give a more striking story to be told to the audience.

Whether you are an architect who wants highly detailed models or a designer who needs quick and efficient results, it is advisable to consult Architectural Model Makers or architectural model services that develop high-quality models according to your project’s needs. Professionals will be able to help you choose the best material for your model and advice on craftsmanship to ensure your model truly represents the concept of your design.

FAQs

1. What is the best material to use for architectural model making?

The best material for architectural model making depends on the purpose of the model. Conceptual models call for lightweight materials; such as foam boards or modeling foam. Acrylic, wood, and metal sheets are great for presentation and final showcase models since they are durable and can show fine details.

2. What are architectural models made of?

Architectural models can be made of a variety of materials, including foam boards, wood, cardboard, polystyrene, acrylic, metal sheets, and modeling foam. The choice of material depends on the model’s purpose, level of detail, and presentation requirements.

3. How do I choose the right material for my architecture model?

To choose the right material, consider the purpose of the model (conceptual, presentation, or final showcase), the level of detail required, your budget, and the ease of assembly. For conceptual models, simple materials such as cardboard or foam boards are sufficient. For more detailed models, you might want to use materials like wood, acrylic, or metal sheets.

4. Can I do 3D printing of architectural models?

Yes, 3D printing could be a great option for architectural models that are detailed and complicated. Resin or PLA materials can be used in 3D printing for making accurate models with geometrically complicated shapes. 3D modeling materials provide accuracy and are good for small parts, especially when combined with more traditional materials for the rest of the model.

5. What is the difference between conceptual and presentation models?

Conceptual models are produced early in the design process to work out overall massing and spatial relationships with coarse materials such as foam boards or cardboard. Presentation models are detailed presentations of more developed designs using finer materials like acrylic or wood. They are to be presented to clients or stakeholders appealingly and effectively, both visually and communicatively.