A Step-by-Step Guide to Model Making

Discover the captivating world of model making, where creativity and precision converge to turn imagination into tangible masterpieces. These models transcend mere representations; they embody meticulous craftsmanship, artistic flair, and technical expertise. Whether you’re an aspiring architect, a product designer, or an enthusiastic hobbyist, this comprehensive guide will lead you through the step-by-step process of creating stunning models that bridge the gap between ideas and reality.

I.Getting Started: Preparing for the Journey

A.Define Your Objective:

The first step in embarking on your model-making journey is to define your objective clearly. Whether you are creating a concept model for an architectural project, a realistic prototype for a new product, or a topographical representation for a landscape design, having a well-defined purpose will serve as a guiding star throughout the creative process. Understanding the goals and intended use of your model will ensure that your efforts are focused and result in a compelling final product.

B.Gather Essential Tools and Materials:

As you venture into the world of model making, assembling the right tools and materials is essential. Your toolkit may include a variety of cutting instruments, such as precision knives, scissors, and saws, as well as adhesives like glue, tape, or even epoxy for joining various components together. Depending on the complexity of your model, you’ll also need measuring tools like rulers, calipers, or compasses to ensure accuracy. Additionally, the choice of materials, such as foam board, balsa wood, plastic sheets, or clay, will determine the final appearance and feel of your model. Gathering these essentials beforehand will streamline your workflow and keep you prepared for every stage of the process.

C.Research and Gather References:

Before diving into the creation of your model, immerse yourself in research and gather relevant references. Studying architectural blueprints, product design sketches, photographs of natural landscapes, or artistic illustrations will help you gain a deeper understanding of your subject and its essential features. These references will serve as valuable guides throughout your model-making journey, ensuring that your creation remains faithful to the original concept while allowing you to infuse your unique artistic interpretation.

II.Crafting the Foundation: Building the Base

A.Draft the Design:

Once you’ve defined your objective and gathered references, it’s time to draft the design of your model. Create a detailed plan that outlines the scale, dimensions, and overall layout of your model. This preliminary sketch or digital mockup will serve as your blueprint, guiding you in the subsequent stages of construction. Pay close attention to proportion and accuracy in this phase to ensure that your model captures the essence of your vision.

B.Choose Your Construction Method:

With the design in hand, you’ll need to choose the most suitable construction method for your model. Depending on the complexity and level of detail you aim to achieve, you may opt for traditional handcrafting techniques or embrace modern digital fabrication methods. Traditional approaches involve cutting, shaping, and assembling materials manually, while digital fabrication techniques like 3D printing or laser cutting offer precise and efficient ways to create intricate components. Selecting the right construction method is crucial, as it will significantly impact the overall process and the final result of your model.

C.Begin the Building Process:

Once you have your design and construction method in place, it’s time to dive into the building process. Carefully cut and shape the chosen materials to create the foundation of your model. This phase demands patience, precision, and attention to detail, as each element you craft will contribute to the overall quality and realism of your model. Take your time, follow your design plan, and ensure that every piece fits together seamlessly.

III. Adding Depth and Detail: Refining Your Creation

A.Layer by Layer:

As you progress, gradually add layers and elements to your model to create depth and realism. Whether it’s adding walls, windows, or intricate patterns, this layer-by-layer approach adds complexity and richness to your creation. Pay meticulous attention to proportions and proportions to maintain accuracy and authenticity.

B.Experiment with Materials:

Explore various materials to enhance the visual appeal and texture of your model. Experiment with paints, finishes, and surface treatments to achieve the desired aesthetics and mimic the look and feel of the real-world object. This experimentation process allows you to bring out the best in your model and add a unique touch to your creation.

C.Lighting and Presentation:

Consider how lighting can impact the presentation of your model. Strategically placed LED lights can highlight specific features, create shadows, and evoke a particular mood. Pay attention to the play of light and shadows as they bring an extra dimension of realism to your model.

IV.Finishing Touches: Bringing Your Model to Life

A.Quality Control:

Before declaring your model complete, conduct a thorough quality control check. Inspect each element for accuracy, stability, and overall presentation. Ensure that all parts fit together seamlessly and that the model meets your initial objectives.

B.Feedback and Collaboration:

Seek feedback from peers, mentors, or clients to gain fresh perspectives and suggestions for improvement. Collaboration with others in the design community can lead to innovative refinements and enhance the overall quality of your model.

C.Preserve and Showcase:

Protect your completed model from damage by handling it with care and storing it properly. Consider creating a display case or platform to showcase your masterpiece. Proudly present your model to others to inspire and demonstrate your skills as a master model maker.

Model making is a journey of creativity, precision, and dedication. As you master this art, you’ll not only bring your ideas to life but also open the door to boundless possibilities in the realms of design, architecture, and beyond. Each model represents the culmination of passion, craftsmanship, and the human imagination. So, embrace the process, hone your skills, and let your models be the tangible testaments of your creative prowess and artistic flair. Let these awe-inspiring creations speak volumes about the world of possibilities that open up when imagination meets craftsmanship in the realm of model making.

Discovering the World Through Miniatures – About Us

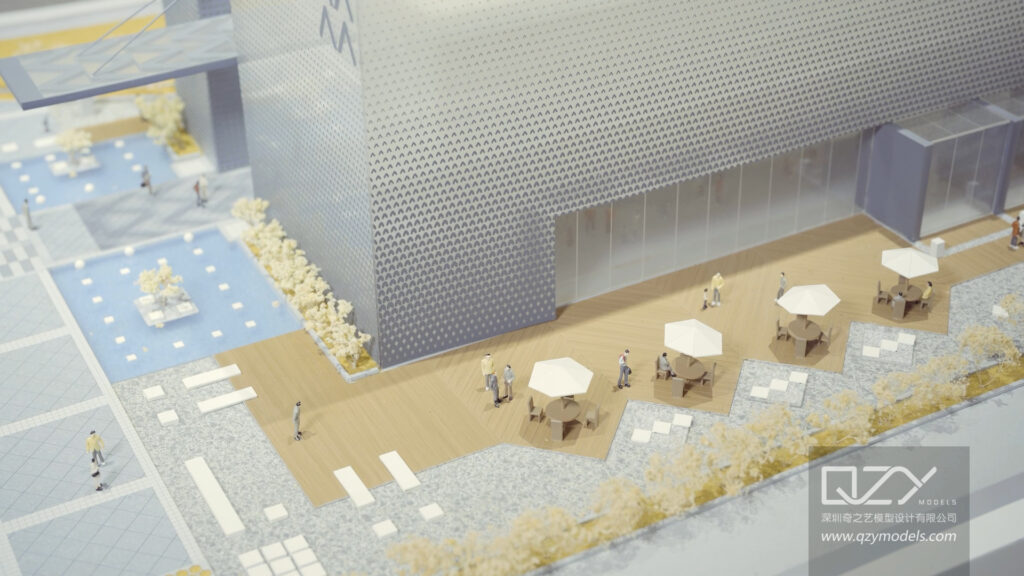

QZY Models, founded in 2013 in Shenzhen, China, is a leading professional team specializing in the design and production of customized physical models. Rooted in the architecture industry, QZY Models caters to diverse model production needs, ranging from furniture, interior design, architectural, landscape, to urban planning. Moreover, we are continuously exploring various fields, including dynamic mechanical models, industrial equipment displays, scientific and technological principle displays, and exhibition displays, to create a diverse model service ecosystem.

Since commencing our independent business in 2013 and establishing our base in Shenzhen, ensuring quality has always remained our top priority. We have forged strong collaborations with renowned companies in over ten countries, such as the United Kingdom, the United States, Canada, and Singapore. Our completed projects span across China, the United Arab Emirates, Saudi Arabia, Egypt, Poland, Morocco, Ethiopia, and other countries. Presently, QZY Models has established branches or offices in Egypt, Morocco, Saudi Arabia, Lebanon, Italy, the Netherlands, and other locations, firmly committed to serving global customers.