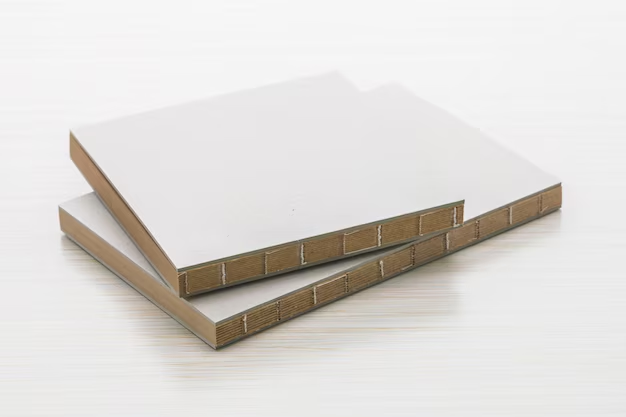

The modeling material is of prime significance in architectural design and presentations, turning conceptual ideas into more realistic and tangible images. Amidst the countless available materials, foam board architectural models have gained popularity among architects, designers, and model makers alike. In this paper, we explore the five key reasons why foam board architectural models offer the best service delivery for precise, visual, and affordable architectural models.

Benefits of Foam Board Architectural Models

In choosing a scale model building material, one has to consider factors that affect not just the quality but also the practicality of making a model. Of all, the foam board architectural model represents an exclusive combination of advantages that positions it uniquely in the sphere of architectural model making.

Lightweight

The lightweight issue is one of the immediate benefits of the foam board architectural model. Unlike the traditional materials of wood or plastic, foam board provides a rigid yet lightweight structure, which is easier to manage, transport, and display. This lightness in weight is quite advantageous when large models are to be made that need frequent movements or are required to be displayed at various places. It also guarantees that even very large projects will remain within the reach of architects and model makers in terms of manageability, so one can concentrate on precision and details, not burdened by massive weights.

Durable

Lightweight construction does not prevent foam board architectural models from being strong. It does not warp, crack, or otherwise degrade with time. The fact that these models are durable means they will not break easily and retain their structure and aesthetic appeal throughout their lives. Besides, the durability makes foam board models highly reliable for temporary exhibitions or long-term displays. Its resilience means intricate designs and fragile details are preserved without affecting the quality of the model through repeated usage and manipulation.

Smooth Surface

Another key advantage of foam board architectural models is the smoothness of their surface. That smoothness allows for perfect detailing and professional finishing, which are very critical in accurately delivering the representation of architectural designs. Smoothness allows paint, adhesives, and other finishes to go on more easily and smoothly, making sure that the finished model will be as beautiful as it is true to the specifications of the original design. A smooth surface also provides a more visually pleasing aesthetic to the model and serves well when presenting it to a client or stakeholder.

Flexibility of Foam Board Architectural Models and Versatility in Design

Foam board architectural models boast versatility and work with nearly any style of design in keeping with an architectural need. This flexibility ensures it remains one of the preferred options for Architectural Model Makers and an interior designer alike.

Flexibility and Ease of Use for Diverse Architectural Model Styles

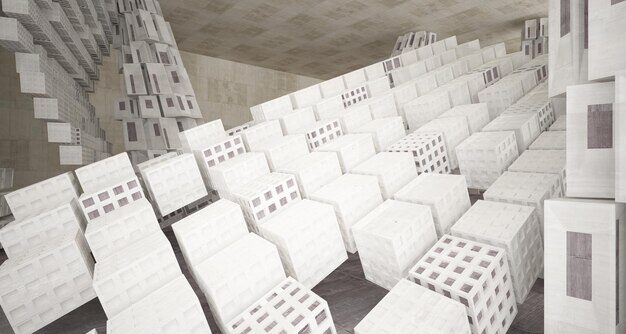

Foam board architectural models offer incredible flexibility whereby designers can effectively manage different architectural styles without effort. Whether it is a modern minimalist design or an intricate classical structure, foam boards can be manipulated to fit into the desired aesthetic. Being pliable, even complicated shapes and forms are achievable without necessarily compromising the structural integrity of the model. This flexibility in foam board is invaluable to architects who work with diverse design languages and need a reliable material that can adapt to different creative visions.

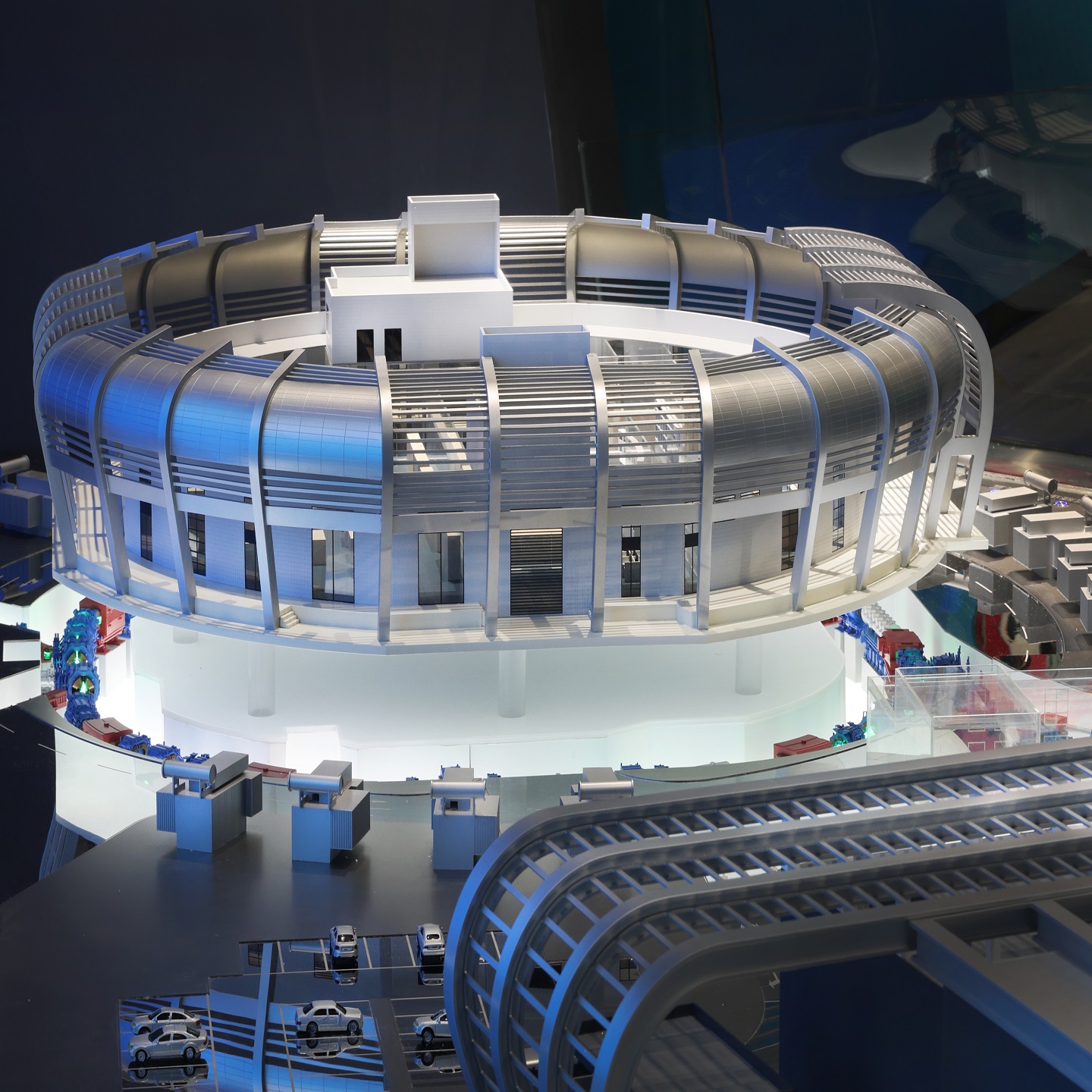

From Small-Scale Residential Models to Large-Scale Commercial Projects: Adaptability to a Variety of Scales Another testament to the versatility is the fact that these foam board architectural models may serve any scale, from compact residential models that require fineness in their details to very expansive and structurally strong commercial projects. This scalability ensures that architects use the same material for various works, as it facilitates scalability in the model-making process and provides consistency in quality. Whether making a detailed facade or an entire building layout, foam board gives flexibility that accommodates various sizes for different projects.

How Foam Board Allows Architects to Experiment with Various Textures, Shapes, and Designs Easily

The architectural models made of foam board give a free hand to the architects to play with textures, shapes, and design elements. This flexibility is particularly helpful during the conceptual stages of a project where several iterations and variations in design may be required. By allowing quick changes and modifications, foam board supports the creative process, enabling architects to try out innovative ideas and refine their designs with ease. This ease of manipulation with foam board tends to encourage experimentation, which in turn leads to refined and well-considered architectural outcomes.

Cost-Effectiveness of Foam Board Architectural Models

The budget for both educational and professional architectural projects is of the essence. Relatively cheaper compared to other modeling materials, foam board architectural models are an affordable option without necessarily compromising on quality or functionality.

Cost of Foam Board Compared to Other Modeling Materials

The cost of the foam board is considerably lower than that of more conventional modeling materials such as wood, acrylic, or even metal. This cost-effectiveness lets model makers be more budget-effective with their resources, thus allowing funds to be channeled toward other critical aspects of the project such as detailed finishes or advanced presentation techniques. Lower cost does not imply lower quality. It is a high-performance material offering great value for money and hence a practical choice for a wide range of architectural modeling applications.

Low Cost Allows Larger or Multiple Models Within Budget Constraints

The affordability of foam board architectural models allows the possibility of creating larger models or multiple copies within the same budget constraints. For example, architecture firms sometimes have to make several models to present different design options to clients. Since foam board is relatively cheap, this requirement is easily met without denting the pocket or blowing the budget to impede the project goals. This, of course, is advantageous in firms that are dealing with many projects at the same time or those projects that require multiple model variations to present comprehensively.

Cost-Effectiveness Makes Foam Board Accessible for Students, Professionals, and Large Firms Alike The economic benefits of foam board extend its accessibility across various user groups. For one, the material is inexpensive enough that students and educational institutions can use it extensively in hands-on learning and experimentation in architectural model making. Meanwhile, professionals and large firms can use the relative inexpensiveness of foam board to create highly realized models for client presentations, marketing materials, and project proposals, ensuring that their creative ideas are well conveyed within often strict budgetary limitations. This wide accessibility makes it certain that foam board continues to be a common material at both the educational and professional levels of architecture.

Easy Assembly and Customization with Foam Board Architectural Models

The ease of assembly and the high degree of customization possible with foam board architectural models are two of the major causes for their wide adoption among architects and model makers.

The Easy-to-Cut Nature Lets Model Assembling Be Easier

The easy-to-cut nature of the foam board greatly simplifies the assembling process to build architectural models quickly and easily. The material could be easily sliced with conventional craft knives or scissors with less time and effort required for building elaborate structures. This simplicity speeds up the process of making models as designers can come up with an accurate representation of their designs more quickly. The ease of assembly also reduces the need for specialized training or experience, which opens it up to a wider range of users.

Simple Tools Like Craft Knives Can Achieve Intricate Shapes and Details

Foam board architectural models are very easy to make into intricate shapes and detailed components. In that regard, precision could be as good with basic tools, such as a craft knife and cutting mat, thus eliminating the need for specialist equipment. Its accessibility is so large, making foam board material of choice by both inexperienced model makers and professionals to create complex and very detailed models with modest tool investment. The fact that such minute detail can be achieved with minimal equipment makes foam board all the more versatile and workable in a variety of architectural modeling contexts.

Customization: Layering, Painting, Texturing-Easy with Foam Board

The compatibility of foam boards with several customization techniques further raises its score. The material allows for layering, creating multi-dimensional structures and realistic features of architecture. Besides, foam board is pretty easy to paint, texture, and finish according to a specific design for high customization. These various capabilities allow architects to create models that closely approximate their creative vision and make sure the final presentation is not only visually compelling but also true to the original design intent. Whether adding color accents or simulating different materials, the flexibility that foam board can provide answers to every need when it comes to sophisticated model customization.

Realism and Visual Impact of Foam Board Architectural Models

Being realistically lightweight and cost-effective, foam board architectural models have not lost any realism and visual effect to achieve those ends. A smooth surface and good adaptability with the reproduction of architectural details, texture, and finishes make for quite realistic and visually impressive models.

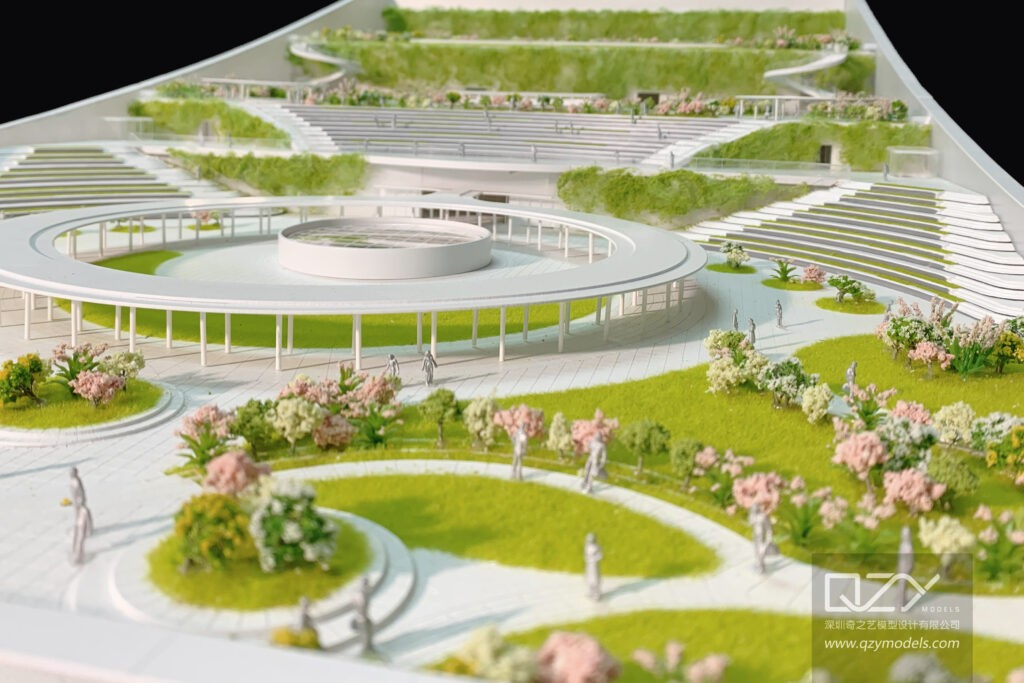

With foam board, architectural model makers can achieve a high degree of detail and accuracy; every minute detail of a design is faithfully reproduced: intricate facades of commercial buildings or nuanced textures of interior space, all are possible with detailed modeling on foam board, which enhances the overall reality of the model. Additionally, painting and finishing the foam board surfaces may further enhance the model’s appearance; hence, it is a strong medium for presentation, pitching to clients, and reviewing designs. More accurately represented materials and finishes on the foam board models better allow stakeholders to envision the final project, thus better-informing decision-making and design refinement.

Final Thoughts

In the final analysis, foam board architectural models have a powerful combination of lightness and strength, versatility in design, economy, ease of assembly, and the potential for high realism that will make them a fine choice for architects, model makers, and interior designers. Whether you are a student embarking on your first project or a professional looking for dependable model building materials, foam board stands out as superior.

The leading provider in the service industry for architectural models, QZY, can also provide a large variety of materials to support the models made of foam board, such as high-quality woods, acrylic, and other advanced 3D-printed components. QZY models let every architectural model maker have access to the superior tools and materials required to bring any creative idea into reality. With QZY’s rich resources, architects can further their model-making to produce highly accurate, detailed, and strikingly beautiful models that effectively communicate their design intent. Whether you need highly specialized interior design models or comprehensive architectural representations, QZY’s offerings support a wide range of design preferences and project requirements.

FAQs

1. Why is the foam board preferred for architectural models over other materials?

These models are preferred because foam board is lightweight, durable, cheap, and easy to modify. All these attributes make foam board an ideal choice for making detailed and accurate models efficiently and economically.

2. Is foam board applicable for small and large-scale architectural models?

Yes, foam board is fairly amenable to any model creation, from a small residential house to large commercial development applications. Due to the malleable state of the foam board, it can be scaled up to preciseness and with intricate details irrespective of its size.

3. What kinds of tools are necessary to operate on the foam board in architectural models?

Working with foam board normally requires only basic tools like craft knives, cutting mats, rulers, and adhesives. These simple tools are enough to cut, shape, and assemble the foam board into detailed architectural models.

4. Is foam board suitable for interior design models as well?

Absolutely, yes, because the smooth surface of the foam board helps in perfecting an interior design model. In interior design, it is always used for viewing interior space, furniture, and all design elements of a particular space, helping interior designers to represent their ideas.

5. How does QZY help architects with the process of making architectural models on foam boards?

QZY supports architects by providing them with a wide range of modeling materials, including foam board, wood, acrylic, and 3D-printed components. Their architectural model service ensures that model makers will have high-quality materials and resources to create detailed and professional architectural models.