Massing models are integral to the architecture design process. A massing model is a simplification that conveys building form, its scale, and spatial relationship in three dimensions. They are used to conceptualize and communicate design ideas at the very beginning of the design process. Such models assist architects, clients, and other stakeholders in assessing the overall structure and refining it before the work gets into minute detail. The paper will review the characteristics, applications, and benefits accruing from physical massing models, which it considers essential in shaping architectural and urban planning projects.

What are Massing Models?

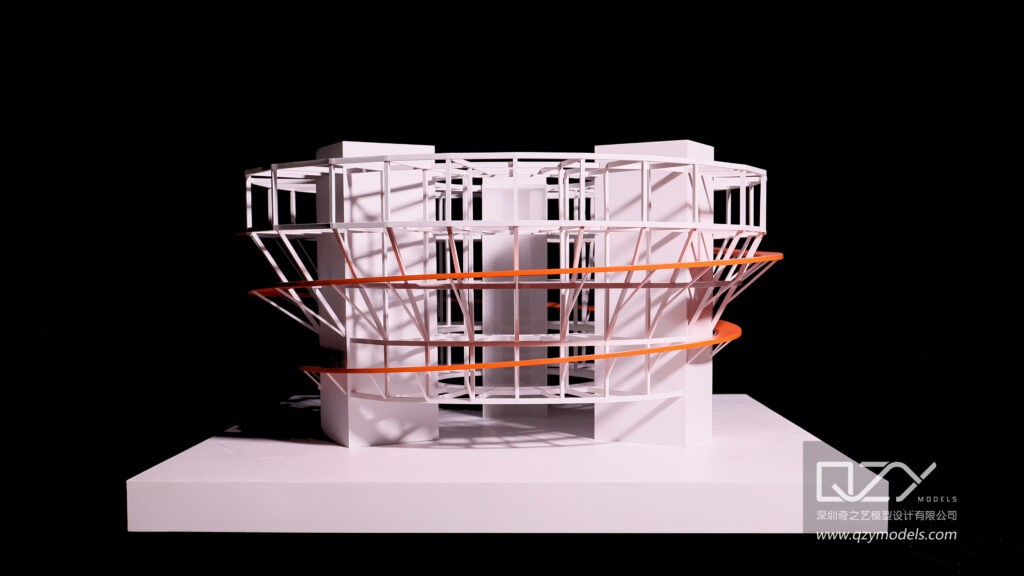

Mass models are simplified three-dimensional representations of buildings or urban layouts in which the key focus is directed to the form, scale, and general composition of the structures rather than the minute details. Commonly constructed from foam, cardboard, or digital renders, massing models support architects and designers in studying and communicating the overall shape, volume, and spatial organization of a project before going further into finer architectural elements.

These models are tremendously important in the preliminary stages of a design as they give stakeholders an intuitive feel for the structure of a building in its environmental context. Massing models are prepared in a different manner from the detailed architectural models, as they do not represent detailed features such as windows, doors, and specific material finishes; instead, they focus on the general framework of the project at hand and its relationship with the surrounding spaces.

Characteristics and Purpose of Physical Massing Models

Visualizing Design Concepts

Massing models put an abstract concept into a tangible form, therefore allowing both architects and clients to perceive the result of a project more clearly. This would be particularly useful in projects dealing with large-scale or complex architectonics, where spatial relationships and the way volumes are distributed are going to be the keys to the overall outcome. In other words, a physical model is how designers intuitively and interactively experiment with proportions, shapes, and scales to seek a design both visually well-balanced and conceptually sound.

Spatial Relationship Analysis

Among all the important uses of the massing model, understanding spatial relationship analysis is one key use that defines different parts of a project regarding each other and to their surroundings. With such a scaled-down version, an architect can study the orientation, adjacency, and hierarchy between various parts of the structure. This serves to accomplish a spatial analysis that identifies how every section of the building is at one with others and perfectly in harmony, taking into consideration the flow of light, casting of shadows, and direction or paths of circulation.

Facilitating Communication with Clients and Stakeholders

Massing models prove to be quite useful in facilitating a well-communicated dialogue between architects and their clients or other stakeholders. They simplify complex designs into understandable forms for the client, who might not be in a position to understand technical drawings or blueprints. In this case, stakeholders can ask questions, suggest changes, and voice concerns about the design, allowing the collaborative and more transparent process of designing. By physically or digitally being presented with a model, stakeholders can envision with ease the impact that the design will have on the surroundings and hence give legitimate feedback early in the process.

Applications of Physical Massing Models

Application to Architectural Design and Urban Planning

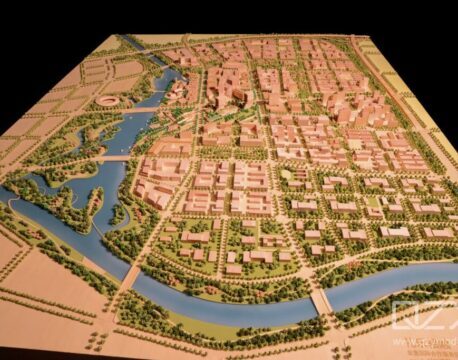

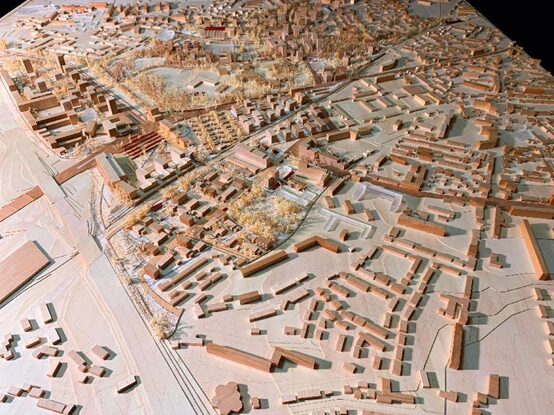

For architectural purposes, the massing model helps the architect deduce the overall general shape of a building, which then forms the groundwork for further detailed design processes. In the case of urban planners and architects, massing models represent several buildings within a site or neighborhood useful in analyzing how new buildings will relate to existing infrastructure and open spaces. Massing models have become an indispensable part of urban planning projects to understand the overall effect of a development on the cityscape, ensuring cohesion and aesthetic harmony.

Role in Presentations and Project Approvals

Massing models are designed to be used in the actual presentations to the client, investors, and public authorities to help them better visualize the project in a clear, concise manner. These models introduce the decision-makers to the holistic view of the proposed design in the project approval stages of its potential impact on surroundings, zoning requirements, and compliance with the local building codes. Through a massing model, an architect and developer can streamline the approval process by enabling the stakeholders to assess the compatibility of the project with the intended setting more rapidly.

Benefits of Using Physical Massing Models

Detection of Design Issues Early

Massing models make the project more comprehensible by providing it on a scaled basis, whereby the problems that might arise in design are easily realized at an early stage. For instance, architects might recognize those strange shapes, discrepancies in scale, or undesired sightlines much earlier before these become costly problems in later stages. The massing models also tend to catch issues with shadow casting onto adjacent buildings, blocking views, or obstructing the urban surroundings in general, this helps avoid design setbacks and ensures a project that is strong structurally and appropriate contextually.

Testing of Design Alternatives

The massing model is one common tool architects use to test different design alternatives: switching out forms, volumes, or orientations to best achieve the project’s objectives. This may be quite a rewarding experimental phase since it allows designers to explore creative solutions and fine-tune the project to further achieve environmental, functional, and aesthetic goals. Architects can take advantage of massing models to test anything from a modernist to a minimalist to a traditional massing scheme in their search for and selection of the best pathway to serve the project at hand.

Cost-Effectiveness Compared to Detailed Models

Physical massing models are a rather inexpensive way to solve the problems of early design analysis. Where the integration of all elements in detailed models takes too much time, massing models is faster and less expensive. They also tend to use available materials and simplified construction techniques, making it a very appropriate tool for architectural offices developing, iterating, and testing ideas without a high level of investment. The cost efficiency will enable firms to invest resources in more complex models or visualizations later on.

Final Thoughts

Massing models are an essential part of the architectural design process, providing a direct, accessible way to explore, articulate, and work out the principal forms of a project. From urban planning and architectural presentations to presenting to and discussing with clients, massing models scale down heavy ideas into comprehensible concepts that establish the foundation of any great design. They bridge the gap between initial concepts and final details, therefore allowing for clearer communication and smoother design processes, which in turn leads to better outcomes for architects and clients alike.

At QZY, we believe that the right massing architectural model is key to ensuring a successful design. Whether you’re at the early conceptual stage or preparing for stakeholder presentations, our custom physical massing models are designed to meet your needs. Contact us today for a consultation and see how we can bring your architectural vision to life.

FAQs

1. What are the common materials used to create physical massing models?

The most common materials for physical massing models include photopolymer resin 3D printing, foam board, ABS, wood, and acrylic. These materials are easy to cut and shape, and they are also very cost-effective, allowing architects to quickly produce prototypes and experiment with multiple design variations.

2. How detailed are massing models in contrast to the other architectural models?

Massing models are typically less detailed and focus on the shape, volume, and scale of the structure. They usually do not include windows, doors, or textures, as these details are reserved for later stages of the design process.

3. Are massing models necessary for small-scale projects?

While massing models are not strictly required for small-scale projects, they can still be very useful. Even for residential or smaller commercial buildings, massing models offer a more intuitive way to consider spatial relationships, especially when the project involves unique shapes or complex layouts.

4. How do massing models differ from digital models?

Physical massing models provide a tactile and concrete representation that is easier for clients to understand and visualize, while digital models allow for quicker modifications and exploration of different design configurations. Both have their advantages, and they are often used together, incorporating elements like 3D projections, LED screens, holographic displays, and multimedia lighting effects to maximize the presentation of the design or to achieve display objectives.

5. What is the typical scale at which massing models are created?

The scale of a massing model is determined by the project size and available space. For large-scale urban planning projects, the scale can range from 1:500 to 1:5000, and in some cases, even as small as 1:8000 for an entire city’s master plan. For smaller building structures, the scale may be 1:50. This allows for a clear representation of the overall structure and gives a sense of scale, without focusing on the finer details.