Architectural models represent an important aspect of the design and planning process, showing a physical version of a building or space that is to be constructed. Choosing the right scale probably constitutes one of the most crucial factors in the model-making process, as it highly affects the success rate at which the model will communicate the design intentions of a project. Scaled models are smaller representations of a larger structure, and by having some knowledge of the different types of scales that can exist, the job of an architect and designer will be clarified, and they can correspond better with the client’s need to see the final product.

In this article, we take a closer look at the most widespread scale used in architectural models, consider factors that typically influence scale choice, and point out some of the most essential advantages of scaled models in architectural design.

Common Scales Used in Architectural Models

Different architectural projects require different scales depending on their purpose, level of detail, and their intended audience. Let’s focus on considering the most popularly used scales:

1:100 Scale

The scale of 1:100 means that one unit on the model represents 100 units in reality. This scale is widely used in architectural presentations because it provides a comprehensive overview of the building while retaining detailed design elements, such as materials, structures, and spatial relationships. Similar scales, such as 1:75 and 1:150, are also commonly used. These scales strike a balance between showcasing details and avoiding the higher costs and larger spatial requirements of larger scales.

Applications: Typically used for final product exhibitions, showing the overall project layout and realistic effects.

Advantages:

- It allows people to quickly grasp the sense of scale, as multiplying by 100 provides the actual size.

- The spatial relationships can be reversed by measurement.

- Accessories for 1:100 models, such as cars, figurines, furniture, streetlights, and greenery, are widely available. This significantly reduces material costs compared to less common scales, such as 1:120 or 1:90, which require custom-made accessories and increase overall costs.

1:50 Scale

In other words, in a 1:50 scale model, 1 unit is equal to 50 units in reality. Such a scale would give further detail and is generally used to depict more detailed features in the design of a building.

Use cases: The 1:50 scale is ideal for residential buildings, smaller projects of commercial entities, or interior layouts. In this regard, the architects are capable of creating detailed floor plans, furniture locations, wall textures, and even material finishes.

Advantages: The 1:50 scale is very good regarding the balance between detail and size. Key features such as windows, doors, and room divisions can easily be shown, thus giving the client a better feel for the internal spaces while keeping the model size within reason.

1:25 Scale

When a model is made to a 1:25 scale, 1 unit in that model corresponds to 25 units in real life. This scale is useful in those situations where high detail is required and therefore more applicable to show nuances of interior spaces or particular building features.

Use cases: It is used in highly detailed interior designs where one needs to view closely the individual rooms or sections of the buildings that require close views of the architectural details, including staircases, bespoke pieces of furniture, or any other special architectural features.

Advantages: At 1:25, the model can include detailed furniture, fixtures, and fittings, thus enabling more realistic presentations. It helps clients and stakeholders understand what the exact look and feel of the spaces will be, including textures and materiality.

1:10 Scale

The 1:10 scale is ideal for showcasing specific architectural details, such as façades, cross-sections, or furniture models. This scale is also frequently used in collaboration with industrial designers for prototyping. It offers higher fidelity in reproducing the texture, grain, and color of materials.

- Use cases: The 1:10 scale is usually applied to show individual parts of the building, such as facades, detailed sections, or furniture models. This is also useful when working with industrial designers who may need to prototype certain elements in the design.

- Advantages: A model in this scale may include specifics like joinery, materials, and structural details. It shows, rather more closely, the reality of how each component will interact with others in the design.

Factors Influencing Scale Selection

The selection of the proper scale for an architectural model is governed by a host of vital factors. Recognition of these reasons creates assurance the model will be serviceable, and effective, and communicate what is to be said.

Project size /scale and complexity

Key factors influencing the choice of scale include the project’s size and complexity, the primary presentation goals, application scenarios, exhibition space dimensions, budget for the model, and destination and installation convenience.

Example:

- Compared to larger scales like 1:300–1:500, a 1:100 model provides greater detail and creates a more imposing presence, but it requires more space and costs significantly more.

- On the other hand, scales such as 1:50, 1:20, or 1:10 capture even more intricate details, such as textures, structural elements, and interior layouts. These include lighting designs, spatial scenes, and various landscaping materials. However, these larger models occupy more space and are more costly. Ultimately, the choice of scale depends on specific needs.

Model Usage

The purpose of the model is the most critical consideration. When creating a physical model, it’s essential to identify its intended use, the key aspects it should highlight, and the audience it targets.

For Sales: Pre-sales display models typically use larger scales with rich details to allow clients to clearly understand the space. Common scales include 1:75, 1:50, or 1:25 for villas or standalone apartments, while scales like 1:100, 1:150, or 1:200 are often used for overall project models, showcasing landscapes, spatial designs, and relationships with surrounding transportation and neighborhoods.

For Early Concept Models: These are often used in the initial design phase to study form and volume. Smaller scales, such as 1:300, 1:400, 1:500, or 1:1000, are typical. These models are smaller in size, lower in cost, and quicker to produce. They focus on overall design styles, structural forms, planning concepts, and spatial or traffic presentations. Such models are often utilized in design competitions, early-stage design research, and educational demonstrations.

Having a clear understanding of your goals and needs ensures the selection of the most suitable design, accurate budgeting, and avoidance of potential pitfalls.

Transport and Display Considerations

The mode of transportation and the display venue are also important considerations when choosing a model design.

Transportation:

- Whether the model is shipped by air, sea, or land significantly affects both time and cost. The choice depends on the project requirements, transportation distance, destination for installation, and the model’s packaging size.

- Air Transport: The maximum packaging size for air transport is generally limited to 3.2m * 2.2m * 1.6m.

- Sea Transport: Packaging can be up to 3.2m * 2.4m * 2m.

- Land Transport: Can accommodate full-size models loaded directly onto a truck.

- Display Venue: The installation conditions and location are crucial when deciding on the model design. For instance, the considerations for installing a model on the ground floor (GF) are very different from those on the 20th floor (20F).

-

- For Ground Floor (GF) installations, we can generally use a maximum model size of 3.2m * 2.2m.

- For higher floors (e.g., 20F), we must consider elevator and door sizes, and whether there is an available elevator. In these cases, we usually limit the model size to ensure it fits within elevator and door size restrictions.

- Other factors to consider include the voltage and socket type at the destination, the stability of electrical supply, whether the country drives on the left or right, and the temperature and humidity conditions. Direct sunlight exposure should also be considered.

Durability

To ensure the model lasts longer and remains stable, several factors need to be addressed:

- Quality and Compliance of Materials: The selection of high-quality, compliant materials is crucial. This includes fire-resistant materials, waterproof and environmentally friendly materials, and the stability of electronic components.

- Environmental Conditions: The model should be kept in environments with moderate humidity and temperature levels. It should be stored in climate-controlled areas that are resistant to water, moisture, and sunlight.

- Manufacturing and Quality Control: Strict technical supervision during production, along with thorough quality checks, will help ensure the model’s long-term stability.

- Post-Installation Maintenance: Professional regular maintenance and protection services are also essential to prolong the model’s life. Proper upkeep will greatly enhance its durability and performance over time.

By addressing these factors, you can significantly extend the life and reliability of the model.

Benefits of Using Scaled Models

From better communication to increased precision in design, the uses of scaled architectural models have many advantages. A few important ones are listed here:

Cost Efficiency

While it is an investment in the making of an architectural model, it also reduces construction costs. A scaled model will be helpful to realize design flaws in an early stage for both the architect and the developer, reducing additional expenses that come in when one alters any part during the time of construction. This becomes very paramount in large-scale projects, where even minor changes lead to significant overruns.

- Insight: These models allow all the stakeholders to get onto the same page with the design before the building starts, preventing a great deal of unexpected costs because of miscommunication or misunderstanding.

More Client Involvement

Mostly, it will be hard for clients to read 2D drawings or blueprints; therefore, it is hard for them to understand what the architect has in mind. Scaled models are tangible and intuitive, letting the client perceive the project much better, therefore enhancing understanding and involvement in the design process.

Example: A 1:50 scale model of the residential project might give a clear view to the clients about how rooms are laid out how light will enter the space, and also how furniture fits into it. This makes them more certain about the design decisions being taken.

Realistic Prototyping

Architectural models stand for the physical prototypes of what the final structure would look and feel like. In this respect, models can be used for realistically testing various design issues, such as structural stability, lighting conditions, and material finishes before actual construction commences.

- Advantage: In the case of larger scales, the view will be to select scales like 1:25 or 1:10 which will allow the architect into minute details about the architectural proposal, such as the nature and appearance that some particular materials will take when joined together thus ensuring that the building emanating from this meets both the aesthetic and functional needs.

Final Thoughts

Selection of the right scale becomes an integral part of the design process in architectural models. Whether it’s a small residential undertaking or a large commercial development, the scale applied influences how the design is communicated, the level of detail that can be captured, and how easily the model can be transported and displayed. By understanding the common scales used in architectural models as well as the factors that influence scale selection the architect and client can make informed decisions that ultimately drive better design outcomes.

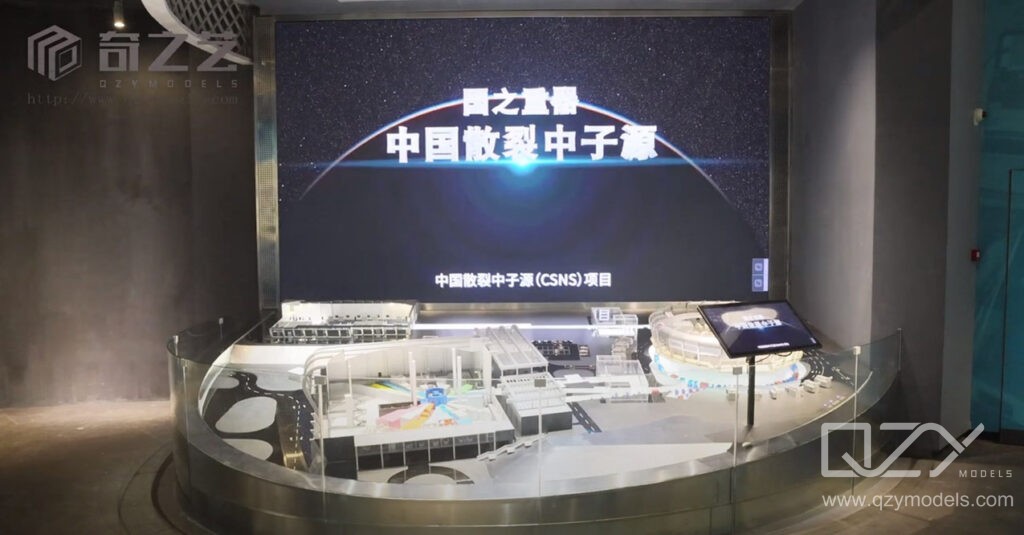

As a leader in architectural model-making, QZY understands how crucial it is to choose the right scale to bring your design concepts to life. With years of experience crafting detailed and precise models, we help architects, developers, and designers transform their visions into reality. Ready to see your project come to life with clarity and accuracy? Contact QZY today and let’s build your next masterpiece together.

FAQs

1. What are the most common scales used in architectural models?

The most common scales in architectural models are 1:25, 1:50, 1:75, 1:100, 1:150, and 1:200. These scales strike a good balance between showcasing the overall perspective of a building and highlighting design details.

2. Why choose small-scale models (e.g., 1:500 or 1:1000)?

Small-scale models are typically used in urban planning or landscape projects where it is important to show the relationship between buildings. They offer a higher cost-effectiveness with moderate detail, and they can be completed quickly within a limited budget and timeframe. These scales are ideal for architectural design studies, preliminary feasibility assessments, or urban design competitions.

3. How do architects determine the appropriate scale for a model?

The choice of scale depends on various factors, including the project’s size, level of detail required, the model’s intended use, budget, time constraints, and transportation conditions.

4. Can scale models be used for interior design projects?

Yes. Scale models are highly effective in interior design as they clearly showcase room layouts, furniture arrangements, and material finishes. Scales such as 1:10, 1:20, 1:15, 1:30, 1:40, and 1:50 are commonly used for interior design projects.

5 .Are digital models replacing physical architectural models?

While digital models have seen significant advancements in recent years, physical architectural models are still indispensable in the design process. They provide a tactile and interactive experience that digital models cannot fully replicate, offering clients and stakeholders a more tangible and immersive understanding of the project.