As the first brand in physical model designing and manufacturing, QZY Models has never stopped its development in the real estate industry, which is shrinking. Several reasons are contributing to our success at QZY Models: excellent quality of the products, loyal customer base, and expertise across several fields. We won our client’s trust through non-stop innovation in industrial model production and maintained steady growth.

One of our most notable achievements is the development of the proton therapy system model in collaboration with China General Nuclear Power Group (CGN). This project highlights our capabilities in creating industrial display models that meet the highest standards of precision and innovation.

QZY Model Introduction

Professional Physical Model Design

QZY Models specializes in creating construction property models, as well as models for industrial, medical, and technological applications. Our diverse portfolio showcases our ability to cater to multiple industries, delivering tailored solutions for each client’s unique needs.

Resilience in a Shrinking Real Estate Market

The real estate industry has faced significant challenges in recent years. Despite this, QZY Models has adapted and diversified, leveraging our strengths in physical model design and expanding into other sectors, including medical and industrial models. This adaptability underscores our commitment to staying ahead of industry trends.

Multi-Field Service Excellence

Success lies in our ability to deliver model design and manufacturing solutions across diversified fields. QZY Models are well equipped to handle projects at every scale and complexity, right from construction property models to radiation therapy equipment models.

Project Overview: CGN Proton Therapy System

What is the Proton Therapy System?

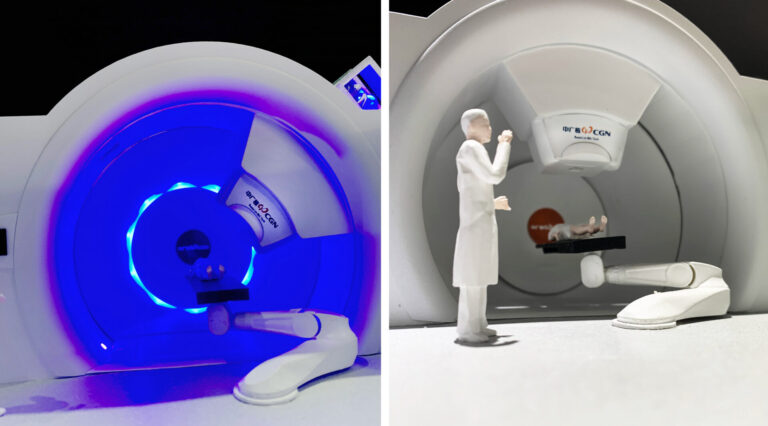

The proton therapy system is a cutting-edge piece of radiation therapy equipment developed by China General Nuclear Power Group (CGN). Unlike traditional radiotherapy methods, which can damage surrounding healthy tissues, this system uses high-energy proton beams to target tumors with unparalleled precision. This reduces side effects and improves outcomes for patients.

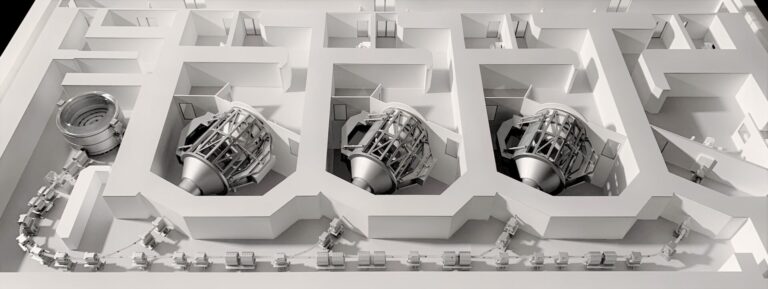

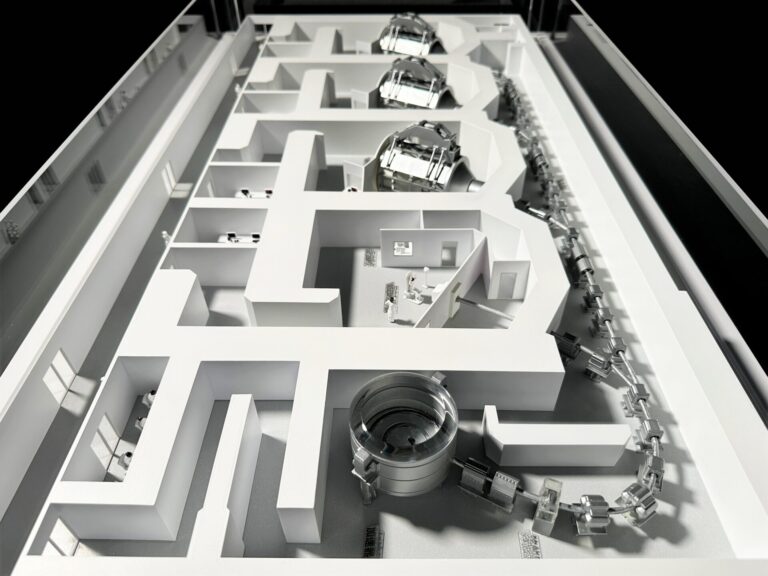

Key Components of the Proton Therapy System

The Proton Therapy system model truly represents the following key components:

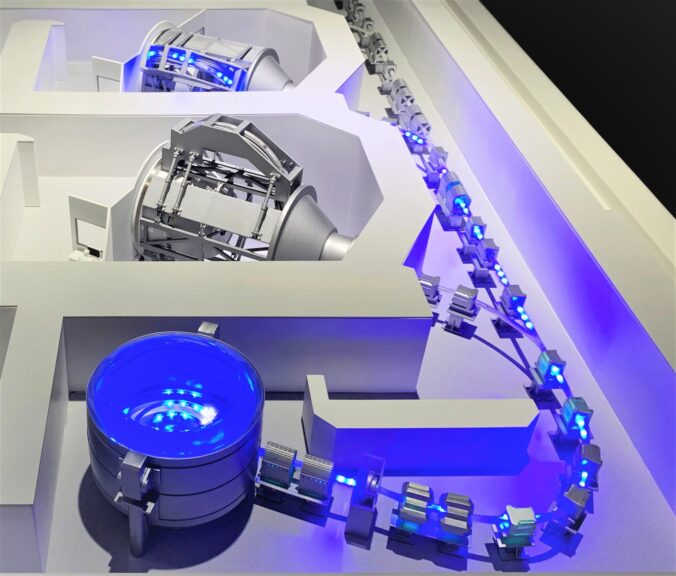

- Proton Accelerator: Produces the high-energy proton beams needed for the treatment.

- Beam Line System: The mechanism is used for guiding and focusing the proton beams to the treatment area.

- Treatment Station: Where patients receive therapy, tailored to the specific type and location of their tumors.

These components work together to provide an advanced solution for tumor treatment technology.

Production Process of Proton Therapy System Model

Model Scales and Locations

China General Nuclear Power Corporation (CGN) commissioned QZY Models to build three demonstration models in different scales of their proton therapy systems. These were the 1:30, 1:50, and 1:70 scale models installed in Shanghai, Chengdu, and Huizhou respectively.

Model Features and Functionality

The industrial display model was scaled down with exact proportions, ensuring that it perfectly demonstrated the principles and processes of the proton therapy system. Key features included:

- Rotating Treatment Room: It presents the shifting of equipment in treatment processes to illustrate their flexibility.

- Fixed-Beam Treatment Room: It focuses on the accuracy of stationary beams for site-specific therapy.

- Laser Targeting Treatment: It illustrates how precise tumor targeting is with highly advanced technology.

Design and Manufacturing Workflow

Our professional design team undertook a meticulous approach to model design and manufacturing:

- Analysis and Experimentation: Thorough analysis of the design of the real system and its functionality took three weeks.

- Client Approval: After presenting our proposal to CGN, full approval was accorded for commencement.

- Production Phase: It took another three weeks to complete the actual manufacturing of the models, meeting our strict timeline.

The final models were lauded for their accuracy in detail and finesse with which they portrayed complex medical concepts.

Challenges and Achievements

Scaling and Precision in Industrial Models

Producing a scaled-down proton therapy system model required a deep understanding of both the system’s technical specifications and the principles of industrial model production. Our team ensured that everything from the proton accelerator to the treatment station was reproduced with precision.

Customer Collaboration and Approval

Collaboration with the China General Nuclear Power Group was required. The team communicated and iterated extensively to meet the specific requirements and deliver models that exceeded expectations.

Final Deliverables and Client Feedback

The completed models were not only visually impressive but also functionally accurate, allowing CGN Proton Therapy to showcase its technology effectively. The client’s positive feedback reaffirmed our position as a trusted provider of industrial display models.

Why Choose QZY Models for Industrial Display Projects?

Commitment to Quality and Innovation

At QZY Models, we prioritize quality and innovation in every project. Whether we’re creating construction property models or advanced medical display models, our goal is to deliver products that stand out for their precision and design excellence.

Professionalism and Timely Delivery

Our experienced team will not delay the delivery without compromising quality. It is very smooth and well-communicated right from the initial design through to the final production to keep our clients informed throughout each stage.

Trust Gained Through Experience

With years of experience in physical model design and manufacturing, QZY Models has built a reputation for reliability and expertise. Our ability to adapt to the unique needs of each client makes us a preferred choice for industrial model production.

Future of Industrial Display Models

As industries evolve, the demand for innovative industrial display models will only grow. At QZY Models, we are ready to meet this demand with cutting-edge solutions that combine technical expertise and creative design. Our work on the proton therapy system model is a testament to our capabilities and sets the stage for future success in the medical and industrial sectors.